PCBs vs. Point-to-Point Construction: Which is better for Circuit Design

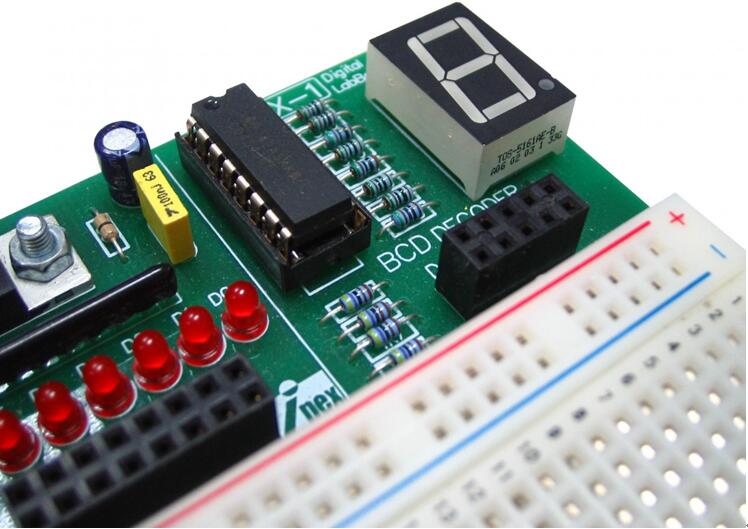

There are two main choices when it comes to making electrical connections; you can either choose to make these connections manually (i.e. point to point wiring and soldering) or you can opt for sleek circuit boards that already have electrical connections (i.e. Printed Circuit Boards).

While the circuit design community is still debating over which option is better than the other, we’ve decided to answer this question logically. We’ve compared the performance of the two wiring options over 5 important aspects in order to determine how point to point construction fares against PCBs.

1. Size:

This one’s a no-brainer; if you want to reduce the size of your machines PCBs are your only option. These devices are incredibly sleek and house tens of layers of copper wiring that can significantly simplify connections and reduce the size of your electrical network.

2. Cost:

There’s no denying the role finances play in swaying people’s opinion. Often people will opt for a subpar option not because they want they’re okay with the quality, but because they simply can’t afford to pay over the odds. The same holds true for circuit designs as even the biggest companies in the world opt for third-party services that cost the least.So, if you subscribe to that school of thought then PCBs are the clear winners as the typical PCB costs less than $5! Furthermore, these PCBs also reduce the overall size of the machine which means that the entire cost of the project takes a major hit and becomes much more economical than ever before.

3. Maintenance and Easy of Repair:

Ask any design specialist and they’re bound to have some horror stories where they spent hours on end trying to find a faulty wire that was affecting the functionality of their electrical device.On the other hand, PCBs are much easier to diagnose as any faults stick out like a sore thumb. Furthermore, these printed circuit boards can also be repaired in no time which further swings this discussion in their favor.

4. Time:

If you’re running low on time and want to quickly make an electrical connection then point to point construction is the way to go. However, if the design is complicated or if you have large orders to meet, then you simply cannot use manual wiring to meet your targets and must rely on the power of PCBs.5. Movement:

No matter which resin you use to hold your electrical connections in place, point to point simply don’t offer the same degree of movement that PCBs do. Simply put, if your electrical network is moved suddenly, point to point soldering would easily be removed while PCBs would remain virtually unaffected.The Final Verdict:

Looking at the arguments made above, it’s clear to see that PCBs are much better than point to point soldering. So, if you want to make sure that electrical devices are robust and reliable, we strongly recommend you opt for PCBs.

If you’re looking for high-quality SMT PCBs, get in touch with Topscom PCB Assembly. The firm is one of the biggest electronic assembly companies in the world and can easily arm you with the tools you need to bring your designs to life!

Pick up the phone and get in touch with Topscom PCB Assembly for top-notch electrical and electronic solutions.