PCB Aassembly cost composition: PCB Assembly fee = PCB board fee + PCB test fee + PCB engineering fee (applicable for small batches) + component procurement cost (partially floating 5%) + SMT/DIP welding fee + PCBA testing fee + assembly engineering fee (applicable for small batches) + special packaging and logistics expenses (if required by customers).

Principles of PCB Assembly quotation:

1. Principles of market and product analysis.

In the face of customer's PCB Assembly inquiry, we need to obtain the evaluation basis from the information retained by the customer (such as email, company name, website, name and title). In order to determine the company's size, market and volume potential, location, price and service acceptance, product added value and other information. In addition, the company's related projects and dynamic information can be obtained through Baidu, GOOGLE, LinkedIN, Weibo and other channels (if possible). All the above work must be completed before the target quotation.

2. Seductive pricing principle.

Giving customers a competitive price does not mean it is the lowest price, especially for developed countries. It is very likely that they will not choose the lowest price, so we need to evaluate carefully and make an intermediate offer without sacrificing profits. For example, it highlights the lower price of the batch display, which is higher than the customer's requirements. In addition, some tests and manual operations can not be included in the process, so that these negotiations will be clear in the future in-depth business cooperation.

3. Embody the principle of specialization.

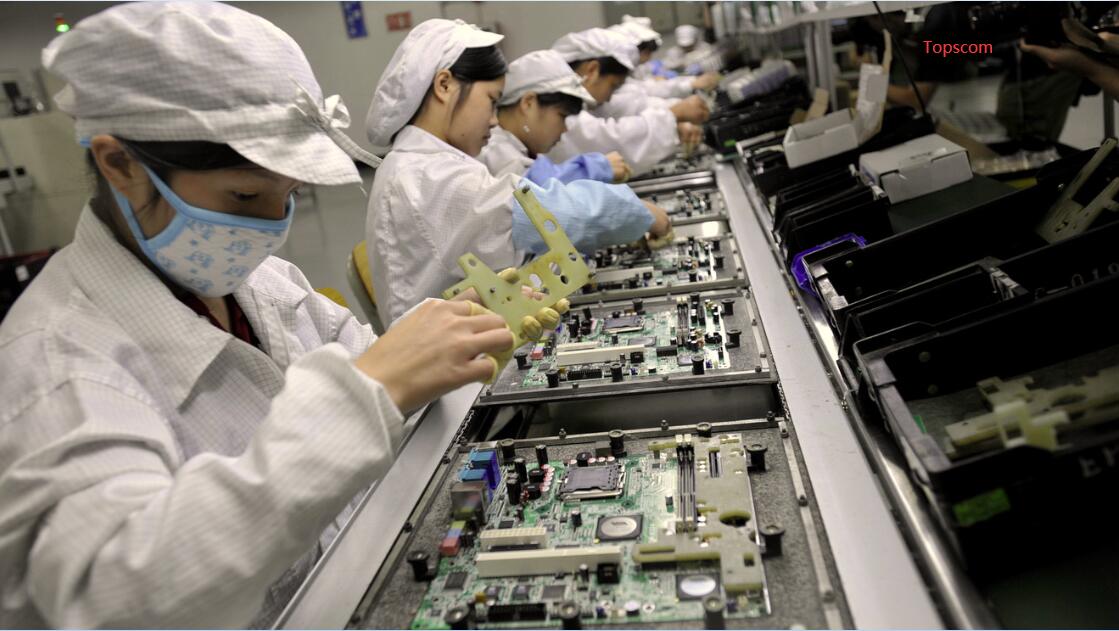

PCB Assembly quotation should be professional enough. PCB Assembly uses the mounting machine to mount some miniature parts to the PCB board, and its production process is as follows: PCB board positioning, printing solder paste, mounting machine mounting, rewelding furnace and manufacturing inspection.With the development of science and technology, SMT can also mount some large parts. It can be reflected in the format of the quotation (such as overall color, font consistency, typesetting specialty, handwritten signature and signature use, etc.), which can give customers a good professional impression. After all, when customers print out quotations from all suppliers for discussion, professionals always make a lot of impression.original author: Mr. lixi Yang China part-time Internet Internship journalist, posted by: china famous PCB assembly ems manufactuer Topscom

PCB Assembly quotation method.

1. Calculate the total material cost according to BOM and Gerber documents.

2. Calculate the cost of SMT patch and DIP plug-in;

3. Calculate the cost of PCB Assembly test (such as ICT,FCT test, etc.);

4. Packaging logistics evaluation;

5. According to the customer's region and product characteristics, generally use cost addition pricing, that is, in the quotation = cost * (1x%), in which x needs to be comprehensively evaluated based on the above information.

Original Author: Mr. lixi Yang China part-time Internet Internship journalist, posted by: china famous PCB assembly EMS manufactuer Topscom

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider