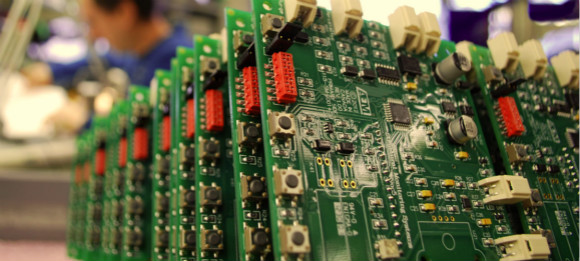

Overview of pcb assembly,what is the pcb assembly?

Did you know that almost all gadgets or electronic devices you use in your daily life have a common basic component? Almost any electronic device, including your PC, laptop, smartphone, game console, microwave oven, TV, dishwasher, etc., will not work without pcb assembly. So, what is pcb assembly?

pcb assembly refers to the abbreviation of a series of technological processes for assembling components on the PCB substrate, and PCB is the printed circuit board. SMT is a surface mount technology (surface mount technology), which is the most popular technology and process in the electronic assembly industry.

pcb assembly technology is called surface mount technology. It is a kind of pcb assembly technology which installs the unpinned or short-lead surface assembly components on the surface of the printed circuit board or other substrates and assembles them by means of reflow soldering or immersion welding.

Method of pcb assembly:

Manufacturers use different types of installation methods according to application, cost, size and other considerations. Here are some of the most commonly used techniques:

Surface mount assembly, also known as SMT, is a method of connecting electronic components that stand upright on a PCB directly to the surface of a circuit board. The final circuit board is called surface mount device (SMD). The technology was originally called "flat placement".

Most of the electronic boards produced at present are made using SMT. Because of its increased circuit density and its ability to produce results on smaller circuit boards, it has replaced the more traditional through-hole technology (more on the next point). Typically, SMT uses solder to connect the component to the circuit board, but in some cases, you can also use an adhesive point on the other side to keep the component in the reflow furnace.

Through-hole technology (also known as "through-hole") is an installation technology in which electronic components are inserted through holes built into the circuit board and then welded to the other side of the pad. Welding can be done manually or by using a plug-in mounting machine.

Through-hole technology replaces the traditional point-to-point structure. As double-sided and multilayer boards become more and more popular, through holes become popular. It is used to connect the component to the conductive layer to ensure the normal operation of the circuit board. These elements are equipped with leads to connect the other side of the through plate.

Electro-mechanical components use electrical and mechanical units to cover a wide range of functions, such as power generation, control switches and other mechanical tasks. Because electro-mechanical components are commonly used in applications with complex cabling and components, components need to be put together manually.