How to Cut Costs by Improving Quality During Contract pcb Assembly manufacturing

With so many manufacturers faced with the prospect of cutting quality in order to cut costs – we’ve learned that a more quality-oriented alternative isn’t just possible, but more viable and effective in the long-term. With this in mind, it’s important to consider the contract assembly process a critical opportunity to add value and lower costs.

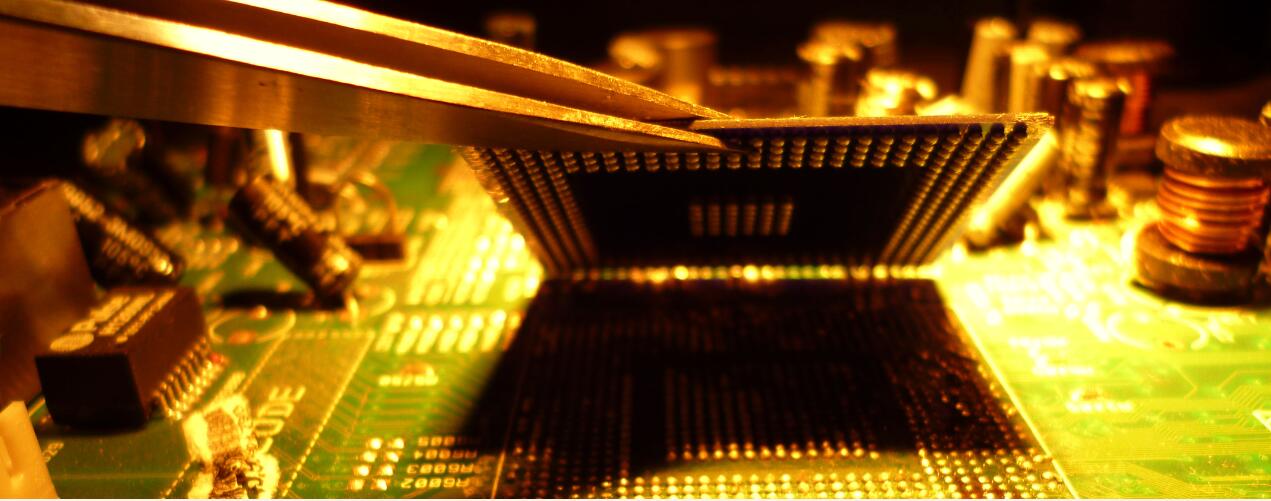

In addition to being low-cost, a company’s PCBA must function well—which means that the assembly process must take into account the tolerances of both the board and its included components. A properly designed PCBA helps to improve quality, reduce manufacturing time and lower product cost.

Quality assembly takes every factor into consideration to help eliminate errors and prevent costly delays. Following, you will find the hallmarks of our approach to maximizing quality and savings throughout the contract surface mount assembly process.

Identify build standards and assembly documentation early: IPC-A-610 is accepted worldwide as a standard for high-quality, high-reliability PCBA assemblies. Some assemblies may require different workmanship standards as laid down by IPC-A-610.

Maximize automation: The more hand assembly you rely on, the greater your costs will be. It’s that simple. There are plenty of automated contract manufacturing companies in the U.S. and abroad that can help you keep costs low.

Minimize damage with careful placement: Components should be placed 6.35 mm from the PCB edge. With regard to potential damage during depanelization, parallel to the edge is better.

Plan for delicate components: Delicate components, such as ceramic capacitors, are at risk of cracking when they are placed too close to the edge. Manufacturing equipment clamping mechanisms require un-obstructed room to grab the PCB effectively.

Component spacing is critical: This is particularly true around ball grid assemblies (BGAs)—.150″ spacing is recommended. This spacing allows enough room for hot air rework tools if upgrades or replacement is required.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider