China Topscom & Top Custom Frames,Racks,Electronics Enclosures, Mechanical Design, Industrial Design,Prototyping and samples manufacturing Company

Enclosure development project stages

Within our company, we carry future devices through the entire process of design and development.

1. Requirements

preliminary research, market survey, pricing factors definition, production requirements implementation

2. Materials

examination of the customer enclosure design based on the selected materials

3. Sketches

the first sketches and 2D/3D photorealistic images in a variety of color and texture solutions

4. 3D modeling

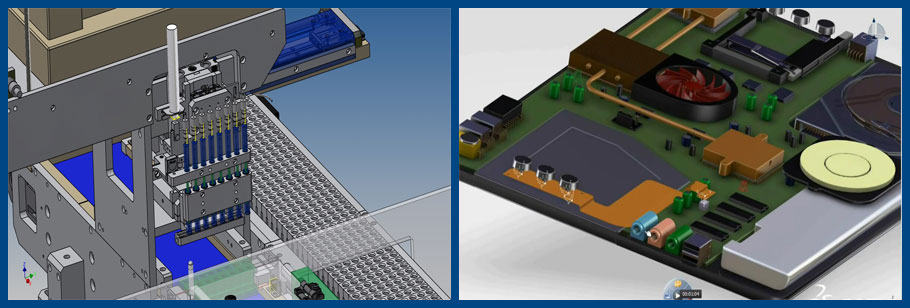

for a more detailed elaboration of the future enclosure, the designer develops a 3D model

5. DFM

enclosure prototyping and preparation for mass production

6. Production launch

we organize production in the right place in the world and provide the necessary consultations

Result: the customer receives a reliable end-device with the required protection against solids, dust, falls, and water with unlimited immersion time to a certain depth. Our industrial designers control the entire process, from creating the concept to the final ready-to-use device.

Materials for electronics enclosures

Thanks to our excellent supply channels, we are ready to work with any materials:

Various types of plastics: ABS, ABS+PC, EK, PC, PE, PVC, PMMA, polyamide plastics, etc.

Woods – different wood species, including composite combinations, such as wood + plastic.

Metals – production of enclosure parts from stainless steel, aluminum, aluminum-magnesium alloys, using multiple technologies (stamping, molding, milling, extrusion molding).

We can also employ other materials in industrial processes, such as rubber, ceramics, glass, etc. at the customer's request.

Expert Engineering Support & Complete Manufacturing Services

It is essential to understand that it is not always possible to use selected materials for mass production at the prototyping stage. For example, you cannot prototype a device with certain types of plastics which are nevertheless successfully used in manufacturing commercial devices. In this case, we use an analog that will reflect the original material's characteristics as fully as possible.

Topscom also provides expert design support for product manufacturing. We can advise on design for assembly and design for manufacturing concerns, as well as provide recommendations to improve performance and lower costs.

Customers rely on our mechanical engineering services to deliver quality and compliance. From plastic injection molding to sheet metal fabrication and box build manufacturing, Topscom can act as your one-stop resource for production services.

With state-of-the-art equipment and integrated manufacturing operations, Topscom engineers are able to leverage efficient machinery and modern processes to help reduce costs. Our staff can review your design and advise on DFA and DFM considerations to allow for accurate production, optimal material usage and maximum value.

Our mechanical engineering services often review needs for sheet metal fabrication, plastic molding, tooling and other components needed in the final box build. Our engineers will recommend manufacturing process, inspection checks and production techniques for your specific design and application.

Our mechanical engineering services often include a selection of the following efforts:

Review of design for manufacturing (DFM) factors

Provide recommendations for spatial concerns, wall thickness and box supports (such as ribs and bosses) to ensure part strength

Review design to ensure optimal cosmetic appearance

Design inserts, hinges and snaps for part function and structure

Recommend materials options based on part volume and budget

Review design and materials in relation to operating and pressure tolerances

Recommend secondary and finishing operations

Recommendations to help lower material and production costs

Topscom can assist throughout the entire product development processes, with in-house 3D printing capabilities that allow customers to evaluate and verify designs before larger production. We can produce prototypes as well as manufacture tooling, jigs, plastic molds and metal fabrications in-house, and act as your one-stop source for complete box build manufacturing.