Precautions for PCB SMT assembly quick proofing: check whether the tin absorbing sponge has water and is clean. If there is no water, please add an appropriate amount of water. The sponge used for welding needs to be cleaned. The contaminated sponge may contain metal particles or sulfur, which will damage the soldering iron head. The utilization rate and loss rate of various materials are difficult to count, which puzzles the material preparation of the workshop and purchasing department. Therefore, the shortage of material preparation of individual parts often leads to the dilemma of shutdown of the whole order equipment. Let's introduce the precautions and problems of PCB SMT assembly rapid proofing.

PCB SMT assembly fast proofing precautions:

1. PCB SMT assembly patch processing: check whether the tin absorbing sponge has water and is clean. If there is no water, please add an appropriate amount of water.

2. The human body and soldering iron need to be reliably grounded. The workshop operators of PCB SMT assembly small batch patch processing plant need to wear electrostatic bracelets and grounded.

3. Before starting manual patch welding, check whether the soldering iron is hot. If it is not hot, first check whether the socket is plugged in. If it is plugged in, if it is not hot, report to the administrator immediately. You can't disassemble the soldering iron at will, let alone directly contact the soldering iron head by hand.

4. The uneven soldering iron head has been oxidized in the PCB SMT assembly patch workshop and needs to be updated in time to ensure good heat conduction effect and welding quality of circuit board. The sponge used for welding needs to be cleaned. The contaminated sponge may contain metal particles or sulfur, which will damage the soldering iron head.

Problems in PCB SMT assembly rapid proofing:

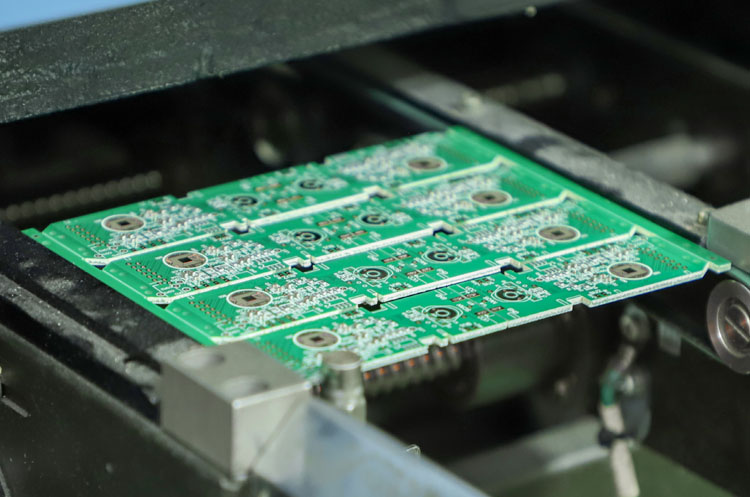

1. PCB SMT assembly patch factories have small batch and multi variety production status, which directly determines that the production site is filled with many different production orders at any time, and the continuous switching of WIP, materials and manufacturing process, which requires the production unit to have efficient scheduling and mixed production planning capacity, and flexibly and effectively meet the production needs of different products.

2. Due to the large variety of materials in PCB SMT assembly production workshop, it is difficult to understand the status of products in time, and the utilization rate and loss rate of various materials are difficult to count, which puzzles the material preparation of workshop and purchasing department. Therefore, the shortage of material preparation of individual parts often leads to the dilemma of shutdown of the whole order equipment.

3. The marketing department requires shortening the product customization cycle to meet the needs of more and more personalized customers.

4. The finance department is complaining that the inventory is too large and takes up too much money. Although the enterprise has invested a lot of human and material resources in the implementation of management information engineering, the production status can not be mastered in real time. Once the order demand changes, the production plan can not be adjusted in time.

5. Due to the lack of timely data and information support at the production management level, the enterprise cannot comprehensively, timely and effectively collect quality data, especially process data, trace the quality source, and generate detailed analysis reports. It is also unable to respond to the problems in the workshop to the managers in real time, so that the same adverse phenomena occur repeatedly, Affect product quality.

The above are the precautions for PCB SMT assembly rapid proofing. What problems exist are introduced in detail. If you have other problems, please continue to pay attention!

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider