China Topscom Provide Integrative solution of electronic contract manufacturing and pcba assembly for automation and industrial control system devices.our factory detailed service include: pcb boards prototype and mass production manufacturing and fabrication,pcba boards assembly,turnkey box build electronics contract manufacturing service.

Automation and industrial control systems are usually referred to as ICS, which is the central nervous system of industrial facilities and automation systems. In the ISA-99/IEC62443 standard, industrial control system refers to "a collection of personnel, hardware and software that can affect the safety and reliability of industrial processes". Industrial control systems usually have the following four functions: 1. Measurement-take the sensor data and use it as the input of the next processing or directly as the output; 2. Compare-compare the acquired sensor data with the preset data; 3. Calculation-calculation of historical errors, current errors and subsequent errors; 4. Correction-adjusts the automation process based on the results of measurements, comparisons, and calculations. The above four functions are usually performed by five components of the industrial control system: the sensor, which is used to measure the physical parameters of the target; the converter, which converts the measured electrical / non-electrical measurements into available electrical signals; the transmitter, which is responsible for controlling the transmission of electrical signals in the system; the controller, which provides the control logic and input / output interface for the whole control system; Actuator-used to change the control process. Modern industrial control system is a control network with complex structure, which is composed of various sensors, controllers, actuators and various subsystems with specific functions. The reform of industrial control system continues, and there are three main development directions: new fieldbus control system, industrial control computer based on PC and integrated technology of management and control system. .

Due to the development of fieldbus control system technology, the development of computer control system will develop in the direction of fieldbus control system (FCS) after experiencing ground-based pneumatic instrument control system, electric unit combined analog instrument control system, centralized digital control system and distributed control system (DCS). Fieldbus control system (FCS) is a bi-directional serial, digital, multi-node communication network connecting field intelligent equipment and automatic control equipment. It is also known as the field bottom equipment control network. The new generation of fieldbus control system is moving from laboratory to practical, which will inevitably affect the prospect of industrial control system. Many people believe that after a period of time, the fieldbus control system will gradually integrate with the distributed control system and eventually replace it. It can be predicted that the programmable logic controller which can follow the fieldbus communication protocol or exchange information with it will become the mainstream of the next generation of PLC and give full play to its advantages in dealing with switch data. Although FCS based on fieldbus is developing rapidly, there is still a lot of work to be done in the development of FCS, such as unified standard, intelligent instrument and so on. In addition, the maintenance and transformation of the traditional control system also requires DCS, so it takes a long process for FCS to completely replace the traditional DCS. At the same time, DCS itself is constantly developing and improving. It is certain that FCS, which combines new technologies such as DCS, industrial Ethernet and advanced control, will have strong vitality. As a flexible, convenient and reliable way of data transmission, industrial Ethernet and fieldbus technology have been more and more applied in the industrial field, and will occupy a more important position in the control field.

Since the industrial PC industrial PC entered the military industrial automation in the early 1990s, it is irresistibly going deep into various fields and has been widely used. The reason lies in the openness of PC, rich in hardware resources, software resources and human resources, can be supported by the majority of engineers and technicians, but also familiar to the majority of people. Industrial control systems based on PC (including embedded PC) are growing at a rate of more than 20% per year. The major programmable logic controller manufacturers and industrial control system integrators have also accepted the technical route of industrial PC, which makes the industrial control technology based on PC become one of the mainstream technologies at the beginning of this century. The low cost of industrial PC is another important factor that is expected to become the mainstream of industrial control automation. In the traditional automation system, the basic automation part is basically monopolized by PLC and DCS, and the process automation and management automation part is mainly composed of a variety of high-end process computers or minicomputers. The high price of hardware, system software and application software deters many enterprises. In the early and middle stages of enterprise development, it is the first choice for enterprises to choose the road of low-cost industrial control automation, and because the controller based on industrial PC has been proved to be as reliable as PLC, it is easy to be accepted by operators and maintenance personnel, easy to install and use, and can realize advanced diagnostic functions, which provides a more flexible choice for system integrators. Therefore, more and more manufacturers begin to adopt industrial PC control scheme in some production. It can be predicted that the competition between industrial PC and PLC will be mainly in high-end applications, with complex data and high equipment integration. From the point of view of the development trend, the future of the control system is likely to be between industrial PC and PLC, and these signs of integration have emerged. For a long time in the future, fieldbus technology, programmable logic controller and industrial PC will complement and promote each other, but the advantages of industrial PC will be more prominent, and its application scope will be rapidly expanded to all industrial control fields.

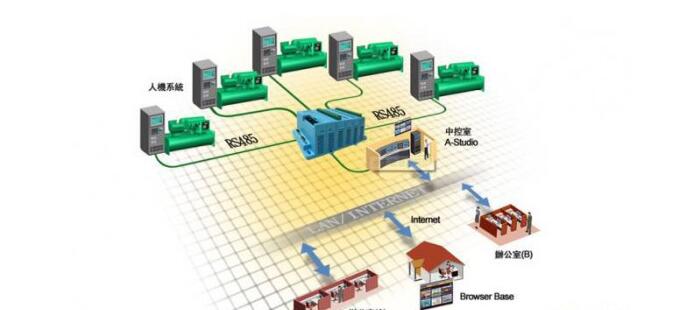

The integration of management and control system with the penetration of Internet technology into the field of industrial control, the combination of control system and management system has become inevitable, which makes it possible for the industrial automation industry to yearn for the goal of management and control integration, industrial enterprise informatization and network-based automation. The integration of management and control can enable enterprises to choose the best solution that is really in line with the new economic era, so as to improve the production efficiency of enterprises and enhance their market competitiveness. Therefore, the new development direction of industrial control technology is to realize open distributed intelligent system through Ethernet and Web technology. Based on the technical standards of Ethernet and TCP/IP protocol, it provides a modular, distributed and reusable industrial control scheme. The most important aspect is to develop network-based control and management software for engineering and chemical industry. The construction of an integrated management and control system, including the integration of a variety of systems and the integration of a variety of technologies. In the aspect of many kinds of system integration, the first is the integration of many kinds of systems in the field control network, which includes three kinds of integration models. The first is the integration of fieldbus control system FCS and DCS, that is, FCS realizes the basic measurement and control loop, and DCS, as the management coordinator of the higher level, realizes complex advanced control and optimization functions. The second is the integration of fieldbus control system FCS, DCS and PLC, that is, when the logic interlock is more complex, PLC and FCS are used to realize the basic measurement and control loop. DCS, as the management coordinator of the higher layer, realizes complex advanced control and optimization functions. The third is the integration of many kinds of FCS, which solves the conversion problem of different communication protocols, focusing on the interoperability of different fieldbus devices and unified configuration, monitoring and software development, in order to achieve seamless integration without losing or affecting the function and performance of each independent system. The second is the integration of the management network and the control network. In the future enterprise management, a large amount of data will come from the control network and build enterprise application software systems, including real-time database, historical database, data release, data mining, model calculation, process simulation, formulation design, operation optimization, parameter detection, deviation analysis and fault diagnosis, etc., through the establishment of various databases in the Internet/Web application network environment. In order to truly realize the integration of management and control. It can provide intelligent decision-making for control software downwards and valuable data for management software upwards. In the integration of a variety of technologies, including equipment interoperability technology, general data exchange technology, EtherNET and industrial Ethernet technology and other technologies integration. The general data exchange technology includes DDE dynamic data exchange technology, NetDDE network dynamic exchange technology, ODBC open database interconnection technology, COM/DCOM component object model and OPC technology. The EtherNET TCP/IP technology can realize the control parameters of the industrial field and the status of each network node to be transmitted and shared directly in the enterprise information network, thus avoiding the situation that it is difficult to integrate PLC, DCS and FCS because of multiple protocols. It is believed that in the near future, driven by the above three technologies, we will be able to see another qualitative leap in the field of industrial control, and human civilization will continue to move forward.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider