China Topscom Group, Multilayer Rigid PCB, High Difficulty & High-Density Interconnect HDI PCB, Microvia, RF, Every Layer InterConnect ELIC PCB, Flexible Printed Circuits, HDI Rigid-Flex Circuits,Semi-flex circuits, FPC, PCBA, China printed circuit board assembly Design & Layout, Quick Turn Prototype, Rapid Fast Prototyping, Mass Manufacturing & Fabrication, China PCB supplier & China PCB manufacturer & Companies.

Offers 24 hours Quick Turn Fast PCB prototype, PCB assembly and Reliable small-batch PCB production.

Best industrial, high level, high difficult, large size, complex structure, high precision turnkey pcbs, box build OEM ODM expert,military quality.

Find best pcbs,assembly,box build OEM ODMs service, Email us: sales@topscompcbassembly.com Whats up: +86 13502814037

Topscom Group is one of the world's leading China PCB manufacturer of advanced China printed circuit board assembly, rank top 20 in china. Special for high end, high complex pcbs, advanced pcb boads fabrication, 2-70 Layer China PCB manufacturing.

China PCB Design & Layout & Fast Prototyping

Professional engineer: 100 +.

Technical expertise: high-speed PCB design, SI simulation, board-level EMC design.

Average annual China PCB design order quantity: 5000 +.

Professional 56g, DDR4, SI/PI high-speed simulation team.

China's national high-tech enterprises, CPCA members, IPC members.

Hold a number of patents related to China PCB design.

PCB Board Rapid Prototypes & Mass Production & Manufacturing & Fabrication

China PCB factory production area of over 12000m2, Over 500 employees.

Production of 70-layer prototypes samples and mass production of China PCB circuit boards.

TPS (Toyota Production System) Lean production Management system.

Corresponding to ordinary China PCB board, M4, M6, Rogers, TU872, etc.

ISO9001, ISO14001, UL, IATF16949 certification.

Over 15 Years of Experience in China PCB Manufacturing, 350,000ft2 monthly | Our products are UL- and RoHS-marked | 2-70 Layer Capablity

Topscom has 15 years of experience in researching and manufacturing PCB China. We provide an extensive range of high-tech prototypes, including HDI boards (5+N+5, stack via and resin plug, laser drill in-house), multilayer boards (up to 70 layers) and rigid-flex boards, along with electronics manufacturing services.

We also use special materials, mostly from Rogers, Teflon, Nelco, Getek, BT and Arlon.Monthly Turnout Reaching 350,000 Square Feet,With a 12,000-square-meter China PCB factory, more than 500 skilled employees and advanced equipment, we are able to produce 350,000 square feet of PCBs monthly. Our facilities house a Hitachi CO2 laser drill machine, X-ray target hole drill machine, AOI machine, Tektronix impedance measurement machines, XY-Dimension micro-test machines and ionic contamination testers. These allow us to complete a 70-layer prototype in as fast as two weeks.Meeting ISO, UL and RoHS Standards,Our QC procedures are in line with ISO/TS 16949, ISO 13485, ISO/TS 14067 and ISO 14001 standards. This ensures that our products carry UL and RoHS marks. Our R&D center consists of experienced engineers who are committed to high-tech China PCB innovation.

From the in house qualification of advanced laminate materials, signal integrity analysis, DFx, Topscom is the leading China PCB manufacturer of advanced China printed circuit board assembly. For both high speed and high reliability China PCB fabrication, Topscoma will work with global based customer to develop advanced PCBs with unique requirements.

PCB Design Layout, CAD, Design for Manufacturability and Cost (DFx)

Quick-turn PCB Prototyping for High Technology PCB China, Backplanes and Flex Circuits

High-volume,capability over 70 layers

Advanced Technology: Latest Laminates, HDI, any Layer Via Structures, Multiple Sequential Laminations

Topscom China PCB factory and Equipment Review:

Everything is becoming digital and the electronics that drive digitization are expected to become even more thinner, lighter, and powerful. Smaller form factors, more stylish designs, and increasingly discrete applications demand Original Equipment Manufacturers to use thinner Printed Circuit Boards (PCBs) that do not compromise on quality or robustness. Topscom offers customers many ways in which board thickness can be reduced. Complete High Speed PCB & Backplane Solutions

Complete High Speed PCB & Backplane Solutions

Topscom provides a fully integrated high speed capability, with in house China PCB design, simulation, signal integrity, EMC/RFI analysis, prototyping and production of custom backplanes, high speed PCBs, cables and enclosures.

Mission Critical PCB China Solutions

Topscom designs and produces high reliability PCBs and flex circuits for defense and aerospace, medical and robust environments. Certifications include: MIL-PRF55110 & 31032, ITAR, AS-9100, TL 9000, Telecordia GR-78-CORE.

High Speed PCBs:

Multiple sequential laminations

HDI, any layer structures

Over 70 layers

Thermal coining

Laser milling

Blind and backdrilled thru holes

High Speed Backplanes:

Panel sizes to 54 inches

Over 70 layers

Blind and backdrilled thru holes

Dual diameter holes

Heavy copper layers

Connector expertise

Topscom China printed circuit board assembly Technology As Below:

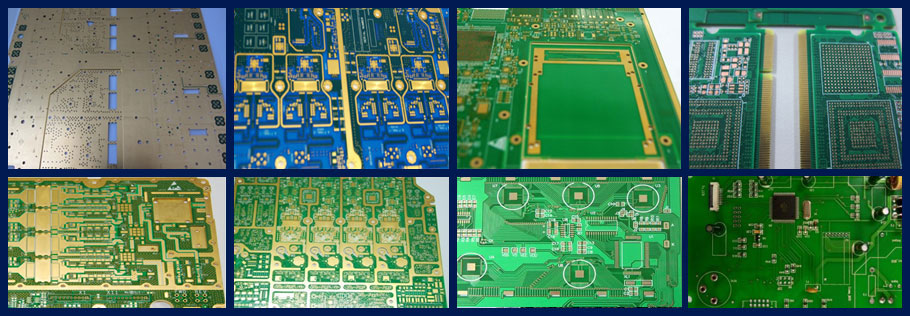

Multilayer Rigid PCB

Complex multilayer PCB processing leadership has been a core Topscom competency for over 15 years. We invest continuously in innovation, capital equipment, and engineering expertise to enhance our technology capacity and capability. Topscom offers early China PCB prototype for New Product Introduction (NPI) to high volume Mass Production. We do all this within the same qualified China PCB manufacturing operations, guaranteeing scalability with optimized cycle times in the quantities your business requires.

Our rigid China PCB mass production capabilities include:

The industries broadest offering of material types

Blind and Buried mechanical and microvia technologies

High-Density Interconnect (HDI) utilizing stacked microvia

High Layer Count Constructions

High-Speed / Ultra Low-Loss Materials

Thermal Solutions with Attached or Embedded Copper Coins

RF Materials and various in-lay or hybrid build-ups

Cavity and Recessed Milling

Back-drilling

Epoxy filled Via in Pad Plated Over (VIPPO)

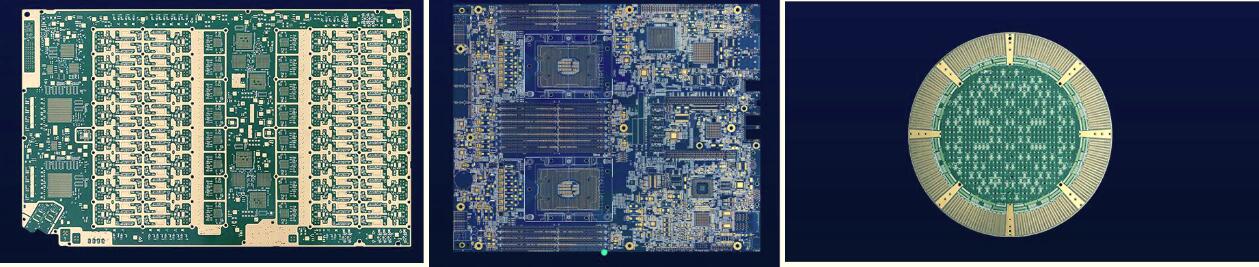

High-Density Interconnect HDI PCB Board

HDI Printed Circuit Boards

High-Density Interconnects (HDI) process technology has continually evolved into China PCB designs since its initial introduction in semiconductor package modules in the late 1980s. Today, drilling laser control depth blind µVias into a variety of laminates, utilizing a variety of copper plating processes, has become the dominant method of HDI fabrication. Topscom's extensive qualification methodology assures the reliability of complex µVia structures in a range of laminates that are thermally robust to multiple PCB SMT assembly reflow cycles. Our Material and HDI development roadmaps are focused on continuous feature size reduction for µVias, which is essential for today's cost-sensitive China PCB design.

Topscom has been a leader in HDI interconnect innovation and mass production for over fifteen years. All of our factories have mass production capacity for µVia-based HDI processing, combined with fine line copper trace formation by semi-additive or subtractive copper plating.

Microvia

Topscom is one of the first companies to provide volume HDI capability to our global customers. Our continuous investment in developing processes for world-class fine-line µVia technology helps us maintain our position as a leader in sophisticated HDI China PCB manufacturer. We provide complete solutions to our customers by early China PCB design reviews to help eliminate potential cost or yield challenges, shortening NPI and production cycle times, and delivering reliable, high-quality products in the most cost-effective ways.

Every Layer InterConnect ELIC PCB Board

For more than a decade, Topscom has continuously innovated next-generation µVia technologies. As the conventional laser via plating technology reached its limits, the Every Layer Interconnect (ELIC) process flow was developed in Topscom China and Germany R&D Labs. Also know as, Any Layer Technology, Topscom's ELIC process was launched into production in 2006. Innovations in laser µVia drilling, copper plating, direct imaging of resists and masks, and improved registration techniques have helped continually refined Topscom's state-of-the-art mass production facility in Zhuhai, China.

Today, Topscom boasts the capabilities for up to 18+ layers of vertically-stacked and copper-filled µVias. Combined with additional innovations in 0.3mm fine-pitch package support, edge plating, and active cavity structures, Topscom offers our customers the flexibility to meet any design challenges. These integrated processes are critical to the thin, high-density assemblies required in the smartphone, computing, IoT devices, modules, and many other products.

Topscom is ready to provide you with end-to-end engineering and production services to bring your next-generation product PCB requirement seamlessly from NPI to mass production with world-class cycle times.

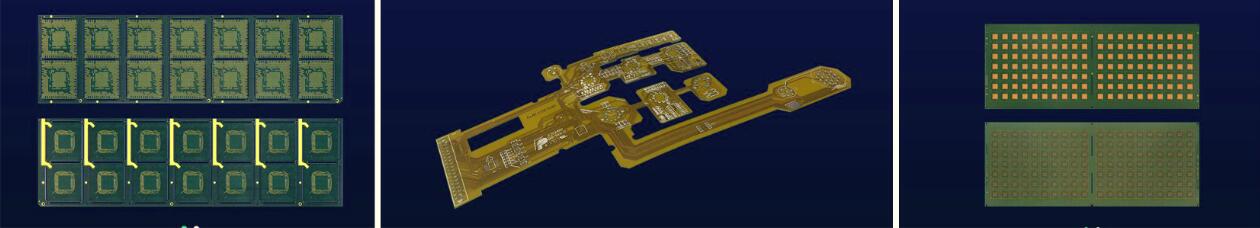

Flexible Circuits FPC

Flexible printed circuits offer dynamic mechanical solutions for electrical interconnect strategies that cannot be achieved with conventional rigid China printed circuit board assembly. With decades of mass production experience, Topscom is an industry leader in fabrication and component assembly for flexible printed circuits.

Our annual production exceeds millions of square feet of single, double-sided, multilayer, and rigid-flex circuitry capacity. We process a wide variety of flexible materials and can rapidly customize solutions to meet our customer's growing requirements.

Single and Double Sided Circuits FPC

Single & Double Sided CircuitsSingle & Double Sided Circuits

Single and double-sided flexible printed circuits from Topscom are utilized in a wide variety of electronic assemblies from simple antennas to complex control circuitry. The single and double-sided flexible circuits are produced using: adhesive based polyester ("PET"/"PEN") or polyimide (PI) film substrates with copper thicknesses ranging from 18um to 140um. These circuits can be provided in single pieces, multiple up arrays, or in rolls.

Key Capabilities:

Single or double-sided circuitry

Adhesive-based and adhesiveless constructions

PI film substrates

Low-cost, Roll-to-Roll manufacturing

Fine line copper etch conductors

Photo imageable solder masks

Laminated coverlay dielectrics

Surface finishes include:

- OSP

- Immersion Silver

- Immersion Tin

- Electroplated Nickel Gold

- ENIG

- ENEPIG

Various support materials can be selectively added, including:

- Metal heatsinks

- Film stiffeners

- Metal, FR4, and CEM1 stiffeners

- Release Films

- EMI shielding

- Molded plastic assemblies

Multi-Layer Flexible FPC

Mulltilayer FPC provides flexibility, and cost-effective alternative to flat cable and expensive connector integration approaches. Utilizing multilayer flexible printed circuits where each layer is produced using adhesive and adhesiveless type polyimide (PI) film substrates bonded together, with or without airgaps for conformal installation. Copper thicknesses ranging from 18um to 140um. Conventional plated hole or µVias, plus coverlay and flexible LPI solder mask circuit protection, are available.

You can choose final-tested circuits in single pieces or multiple up arrays, with lead-free reflowed PCB SMT assembly. These include component solder attachments on single or double-sided circuit sections with adhesively-attached stiffeners.

Key Capabilities:

Multilayer circuitry-from 3 to 16 layers

Adhesive-based and adhesiveless constructions

PI film substrates

Fine line copper etch conductors

Photo imageable solder masks

Laminated coverlay dielectrics

Surface finishes include: -

OSP

- Immersion Silver

- Immersion Tin

- Electroplated Nickel Gold

- ENIG

- ENEPIG

Various support materials can be selectively added, including: -

Metal heatsinks

- Film stiffeners

- Metal, FR4, and CEM1 stiffeners

- Release Films

- EMI shielding

- Molded plastic assemblies

Rigid-Flex Circuits FPC

Rigid Flexible Circuits have become a preferred design solution for complex, three-dimensional product assembly, and advanced component surface mounting demands.

Topscom provides advanced integration of high volume rigid board technologies with sophisticated integrated flex circuit layering. Through Topscom's engineering of materials and fabrication processes, we offer exceptional mass production capability and capacity whether a consumer device, automotive, industrial, medical, or high-speed telecommunications, Topscom has a fully-qualified solution.

Standard Rigid-Flex FPC

Standard Rigid-Flex provides a cost-effective alternative to rigid Printed Circuit Board (PCB) modules and Flexible Printed Circuit (FPC) interposers/connector systems. Topscom integrates conventional plated through-hole, and microvia interconnect processing for intermediate component density designs to give you the best Standard Rigid-Flex solutions. Topscom incorporates stiffeners, air gap construction, shielding, and coverlays from our FPC systems as needed.

With prequalified materials from our matrix of low-cost, Asia-sourced rigid and FPC laminates, coverlays, stiffeners, and shielding, Topscom provides end-to-end solutions optimized for cost-sensitive applications. Topscom offers engineering support during the design and specification phase, to create an optimal bill of materials and stack-up to deliver low cost, high processing, and China PCB assembly yields, and the best reliability.

HDI Rigid-Flex FPC

Topscom provides industry-leading HDI capabilities to optimize today's challenging designs. The use of HDI and Every Layer Interconnect (ELIC) stacked copper filled µVias, fine feature etching, and precision registration provide unique, mass-production solutions for complex designs.

With extensive investments in leading-edge production systems, rigid HDI PCB Topscom can build the next generation of interconnect solutions.

Rigid-Flex designs utilizing HDI/ELIC capabilities eliminate the need for the module connectors and saves precious space within the slim, high-style designs compact designs. Topscom provides this new end-to-end solution from initial design to mass production. Our Global Engineering, ITC, and Business teams are ready to help you quickly transform ideas into new interconnect platforms that achieve mass-production scale.

Semi-flex circuits FPC

Semi-flex circuits have become a preferred design solution for cost-effective three-dimensional product assembly. Topscom provides the industry-leading expertise to integrate high-volume rigid board technologies with flexible circuit capabilities on standard material sets.

Features

No dielectric damage in the bend area

Tight dielectric thickness control in the bend area

Inner or outer bending layer

Solder mask or coverlay can cover bend area

Applications

Flex-to-install application

Limited bending cycles

Large bending radius

Thermal Management

Thermal challenges are growing concerns with today's designs. From component density issues, reduced thermal paths, and increase power amplification, these present challenges to help dissipate heat within the design of the PCB China. To help minimize these issues, Topscom provides a broad suite of innovative thermal management solutions.

Through the use of embedded heat transfer techniques, Topscom can offer processes for solid-plated µVia arrays, embedded metal structures ("Coins"), both flush mounted or cavity recessed, and surface-attached heat transfer media. These technologies offer a wide range of thermal dissipation within the PCB, and Topscom engineering has industry-leading expertise in thermal solutions.

Thru-Hole Via Farm

Utilizing dense via formations can help improve thermal dissipation from the component side to the backside of the PCB. Topscom can provide increased redundant via structures in both thru-hole, and µVia deigns.

COIN

For enhanced heat dissipation in power amplifier boards, network products customers are designing with “COINS” technologies into high ASP 10-16 layer count PCBs. Three different copper COINS technologies have been setup in Topscom China.

Inlay

In response to new system performance demands in the wireless infrastructure market, Topscom introduced our first inlay Printed Circuit Board (PCB) technology in 2013. In prior product applications, a full panel FR4 material is applied in hybrid stack-up construction with an entire panel core of expensive high frequency yet low loss material, resulting in an expensive finished product.

To reduce total panel cost, Topscom introduced selective semi-finished inlay circuitry using high-frequency laminate, into the overall FR4 laminate panels using 3D structuring. With only a small part of the final China PCB design area specified for high-frequency signal transfer, our inlay innovations reduce the amount of high-frequency laminate and allow integration of our thermal solutions into your final optimized design. A full design guide is available upon request.

Topscom PCB Circuit Boards Plants Basic Info:

- Multoc Circuit Co.,Ltd. Established in year 2001 And 100% Subsidiary Company is Invested By Topscom

- China PCB factory Location: Multoc Building Park,Futian Industrial Zone, Dingnan City, Jiangxi Province,China.

- Initial Capital of $9,000,000

- Accredited ISO9001 ISO13485 ISO 16949 ISO14000

- Factory production area of over 12000m2

- Over 500 employees

- Sales Revenues: 80 Million USD with 2016 year

- pcb circuit boards manufacturing, China PCB service for China PCB manufacturing a wide range of products including: Automotive, industrial, medical, consumer, telecom, and Aerospace Devices

- Pcb include: Multilayer Rigid Pcb, HDI Pcb, Over 70 Layer, And Flexible Circuits Pcb, Rigid-Flexible Circuits Pcb.

-Products are 100% exported from China, primarily to Europe and North America.

Learn more about our customer focused solutions, products and services by contacting Topscom today.

Contact Topscom Group Now:Email:sales@topscompcbassembly.com Mobile: +86-13502814037 (what's up) Ms.Angelina Joo