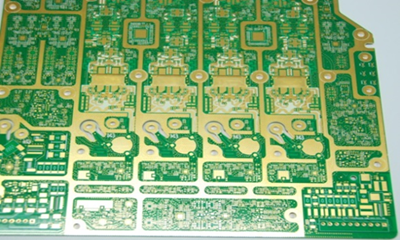

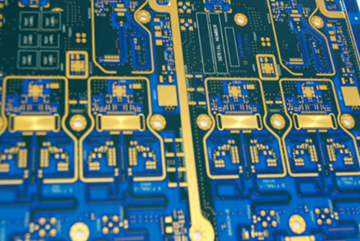

What is the pcb boards cost? If u want more pcb manufacturing info pls see : #pcbfab#

Many purchasing staff of electronics factories have been puzzled by the changeable price of PCB. Even some people who have many years of PCB purchasing experience may not fully understand the reason. In fact, PCB price is made up of the following factors:

1. Different materials used in PCB lead to the diversity of prices.

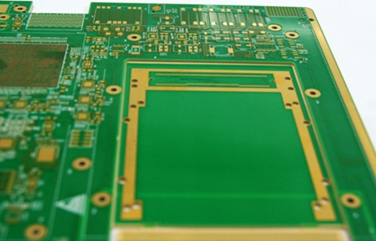

Take the ordinary double panel as an example, the sheet metal generally has FR-4,CEM-3 and so on, the thickness varies from 0.6mm to 3.0mm, and the copper thickness varies from & frac12;Oz to 3 Oz, all of which cause a huge price difference in the sheet metal; in terms of solder resistance inks, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil, so the diversity of prices is caused by different materials.

2. The diversity of prices is caused by the different production processes adopted by PCB.

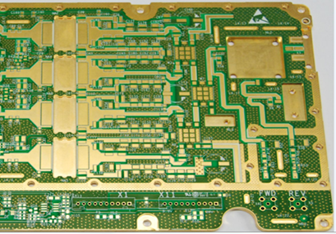

Different production processes will cause different costs. Such as gold-plated plate and tinplate, the production of shape gong (milling) board and beer (punch) board, the use of screen printing circuit and dry film line will form different costs, resulting in price diversity.

3, the price diversity caused by the difficulty of PCB itself.

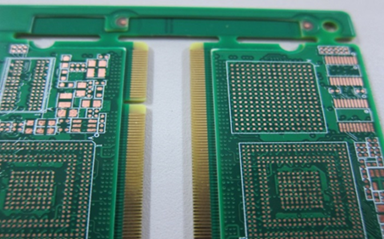

Even if the materials are the same and the processes are the same, different difficulties of PCB itself will result in different costs. If two kinds of circuit boards have 1000 holes, one board aperture is larger than 0.6mm and the other board aperture is less than 0.6mm, different drilling costs will be formed; such as the other two kinds of circuit boards are the same, but the line width is different, one is greater than 0.2mm, the other is less than 0.2mm, it will also cause different production costs, because the difficult board has a higher scrap rate, which will inevitably increase the cost, resulting in price diversity.

4, different customer requirements will also lead to different prices.

The level of customer requirements will directly affect the finished product rate of the board factory, for example, a kind of board has a qualified rate of 98% according to IPC-A-600E,class1 requirements, but only 90% qualified rate according to class3 requirements, resulting in different costs of board factories, and finally lead to changeable product prices.

Price diversity caused by different PCB manufacturers.

Even if the same product, but because different manufacturers have different processes and equipment and different technical levels, there will be different costs. Nowadays, many manufacturers like to produce gold-plated plates because the process is simple and the cost is low, but there are also some manufacturers who produce gold-plated plates, which increases as soon as they are scrapped, resulting in higher costs, so they prefer to produce tinplate, so their quotation for tinplate is lower than that of gold-plated plate.

5. Price differences caused by different methods of payment.

At present, PCB board factories generally adjust PCB prices according to different payment methods, ranging from 5% to 10%, resulting in price differences.

6. different regions lead to the diversity of prices.

At present, in terms of geographical location, from south to north, the price shows an increasing trend, and there are certain differences in prices in different regions, so different regions also cause the diversity of prices. How to calculate the PCB quotation!

1. Plate cost (different plate cost is different).

2. Drilling cost (the number and size of holes affect the drilling cost).

3. Process cost (different process requirements of the board lead to different difficulties in the process, and even the price will be different).

4. Artificial water and electricity plus management expenses (this cost depends on the cost control of each factory, relatively speaking, Taiwan-funded factories are relatively low in many countries).

This is the basic composition. As for the price of raw materials, it is now basically stable, and the possibility of price increase is slim.

What the above brother said is right, but it is not comprehensive and detailed. Let me add one more thing:

As far as sheet is concerned, the price is mainly affected by the following points:

1, plate material: FR-4,CEM-3, this is our common double-sided and multi-layer plate, his price is also related to the thickness of the plate and the thickness of copper and platinum in the middle of the plate, while FR-I,CEM-1 these are our common single-sided plate materials, and the price of this material is also very different from that of the above double-sided and multilayer plates.

2, is the thickness of the plate, its thickness is common to us, that is: 0.4Magne0.6, 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 3.0, 3.4, and the price difference of the thickness of our regular board is not very big. (2) the thickness of the plate is the thickness of the plate, and the thickness of our regular plate is not very different from that of our regular plate.

3. The thickness of copper and platinum affects the price. The thickness of copper and platinum is generally divided into 18 (2/1OZ), 35 (1OZ) 70 (2OZ), 105 (3OZ), 140 (4OZ) and so on.

4. Suppliers of raw materials are common and commonly used: Shengyi Jiantao International and so on.

Process cost:

1. If you want to look at the lines above the PCB, if the lines are dense and thin (below 4/4mm), the price will be calculated separately.

2. There is also a relative increase in the cost of the board with BGA,. In some places, how much is BGA?

3, depends on what surface treatment process, we commonly have: spray lead tin (hot air leveling), OSP (environmental protection board), spray pure tin, tin, silver, gold and so on, of course, the surface process is different, the price will be different.

4, also look at the process standards; we commonly used is: IPC2 level, but there are customer requirements will be higher, (such as Japanese capital) We are common: IPC2, IPC3, enterprise standard, military standard and so on, of course, the higher the standard, the higher the price.

Every PCB sold in the PCB industry is customized by customers, so the quotation of PCB needs to be calculated first, and at the same time, it needs to refer to the automatic collage calculation of PCB computer, and make a comprehensive quotation for the material utilization of typesetting on standard size copper clad laminate.

The cost calculation of PCB industry is the most special and complex of all industries. From material opening, pressing, forming to FQC, packaging, completion and storage, it needs to be calculated step by step according to the material cost, labor cost and manufacturing cost invested in each process, and then accumulate the cost in batches according to the order product number. And different types of products, the standard rate of their processes will be different. For some products, such as blind burying hole plate, gold sinking plate and pressing copper seat plate, some special calculation methods must be adopted because of the particularity of their process or all materials. Similarly, the size of the drill bit used in the drilling process will also affect the cost of the product, which directly affects the calculation and evaluation of WIP cost and scrap cost.

In addition, PCB factories belong to OEM customer OEM products, different customers have different customized products, there are few shared products. On the other hand, for the sake of quality, some customers may also specify the use of a manufacturer's substrate, or ink, etc., to meet their quality and cost control requirements.

Fast fish eat slow fish, and only by responding quickly to changes can they survive.

ECN (Engineering change Notification) change.

ECN engineering changes often occur in the production process of PCB industry products, and there are often both internal ECN and external ECN changes (customer engineering document changes). Frequent ECN changes in product design, if not managed properly, the scrapped inventory will be very amazing. Therefore, how to plan the application of ECN product design changes in ERP system is a very critical and important thing.

If the material numbers of products and semi-finished products are changed regardless of ECN major changes or small changes, it will make it impossible for the personnel of various departments to figure out whether each different version of the product is compatible and whether different material numbers can be delivered, which will cause a lot of inventory or work-in-process unnecessary scrapping in the event of ECN product design changes.

Planning and establishment of BOM data.

The planning and establishment of basic BOM data is as important to the PCB industry as the foundation of a building. If the foundation is not laid well, the building will not be built, which is an inevitable truth.

Basic engineering data consists of two parts:? Basic material data management. ? Product structure BOM management. The PCB industry is a rapidly developing industry, material consumption and processes will change due to technological progress, some materials and processes will no longer be used after a year or two, while some materials and processes will increase due to the progress of production technology and R & D technology. As a result, there will be a lot of changes in the PCB industry in terms of basic data.

Another feature of the PCB industry is that for the sake of quality, some customers will clearly specify that they will only accept materials produced by one or several raw material manufacturers.

How to ensure delivery time?

The short delivery cycle of ERP industry requires production management to control the whole production process from order issuing to production completion, which requires the PCB system to provide production scheduling and work-in-process management to ensure production delivery and customer response speed. Therefore, the key competitive advantage of PCB lies in engineering research and development, health management, material control, manufacturing, outsourcing processing and other links, especially the WIP (work-in-process) control of on-site production management. If WIP is not properly controlled, there will be many mismanagement phenomena, such as mixed version, loss, stagnation, inaccurate quantity of WIP, delay of replenishment, increased number of line changes, unknown delivery time, and so on.

There are many kinds of products in PCB industry, which are generally distinguished according to the number of layers, such as single panel, double panel, four-layer board, eight-layer plate, ten-layer board and so on. The processing materials, technological process, process parameters, testing methods and quality requirements of PCB products will issue processing instructions to the production department and outsourcing units by compiling the production instruction (MI).

For products with four layers and below, the technological process is relatively simple, and the production process card can be completed from beginning to end, and there is no need to change the process or replace the process card. As for the blind buried hole plate products with more than six layers, because different inner and outer layers have different circuit diagrams, technological processes or process parameters, as well as different moulds, films and other auxiliary equipment, it is necessary to use different production instructions and related documents, and different production process cards will be made in the production process to control the manufacturing process and quantity of different inner and outer layers.

In the production process, the multilayer board will have different inner codes, which must be distinguished by different codes in the production process, and the production progress must be controlled by different production process cards. PCB is the transfer and handover of (LotCard) auxiliary products through the production of batch cards, commonly known as the past number. Due to the large number of online products and miscellaneous models, it is required that the over-count operation, scrap operation and repair operation should be simple, fast and fault-tolerant. In the process of implementation, I deeply feel that general-purpose ERP products are basically unable to deal with the business of coding, counting, scrapping and replenishing the inner and outer layers respectively.

Generally speaking, the more detailed the production plan, the richer and more valuable the information it gives, and the more difficult it is to calculate. The more rough the production plan, the less information and value it will be. However, the technological process involved in PCB is often more complex, the engineering data of a complex PCB multilayer board and the production of MI often take a long time to complete, and the delivery time required by customers is often very urgent. For the production management of PCB manufacturing industry, it belongs to the manufacturing mode of process flow, so small scheduling (Run Card scheduling) management technology will be adopted. Therefore, when scheduling, we must pay attention to the following PCB production process characteristics:

Reflux processing.

PCB processing is a representative process processing, which is different from the mechanical assembly processing mode, it is mainly by a kind of raw material input, and the subsequent auxiliary material input and processing technology are all around the main raw material. And due to the emergence of multilayer technology, reflux production (that is, repetition of a certain or a certain processing process) in the PCB industry is also more and more common.

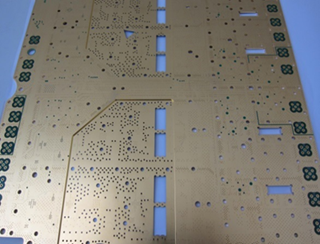

Cutting and pressing.

Whether it is the substrate processing of the front section or the output of the PCB board of the rear section, a link that must be experienced is continuous cutting. The input in the front section is a large amount of raw cloth, which will be cut to a reasonable size for subsequent processing in order to meet the needs of subsequent processing. Another process is pressing, whether it is the front processing substrate or the back processing of multi-layer plates, all need to carry out pressing work, that is, two plates with the same area shape are pressed into one, especially in the case of multi-layer plates.

For the characteristic of cutting and pressing, that is, how many raw materials are needed to process a certain number of finished products, the number of large plates is converted into the number of small plates, from which the input of raw materials is calculated. However, when there is a waste / waste situation, combined with the proportion of father and son work orders, it will sometimes lead to an increase in the workload of the PCB plant and the unsmooth and incoherent treatment of the process.

Monolithic scrap.

Different from the scrapping of the assembly industry, the scrapping of PCB has so-called monolithic scrapping in addition to scrapping (excluding scrapped products). The reason is that the pressing process is usually carried out for the large board, a large board will generally produce a different number of final monolithic products. When there is a defect in the pre-pressing process, resulting in poor quality at some point on the single panel A or B, the production staff can not simply throw away the large board, but continue to use the material, but will record a single scrapped quantity for the single panel.

For example, a large board A can be finally cut into 16 small PCB boards, but in the current processing process, a certain point on the board is damaged due to technological problems, so the result of this batch processing is that the scrap number of the large board is 0 (no whole piece is scrapped), and the single piece is scrapped to 1. This quantity will accumulate backward with the flow of the process for production statistics and final product output. At this time, it should be noted that the scrapped quantity of a single piece will be inherited by the double board after passing the pressing operation. Because after the pressing of single panel A and single panel B, the projection of bad points on board A will also cause bad points on B, and the resulting double-layer plates will not be used at this point, resulting in the same number of scrapped pieces.

Finally, the PCB industry is a contract manufacturing industry, product design changes are very frequent, often change the version. Once the customer changes the version, the manufacturing instructions and process cards also have to cooperate with the change, and there may even be some changes and some no changes.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider