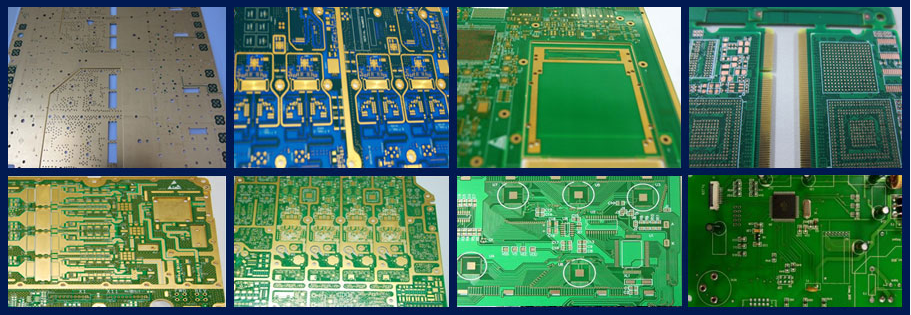

China Topscom issured a article on china pcb world magazine about the key technologies for the manufacturing of pcb printed circuit boards in the May of 2020.

1. Integrated technology.

The manufacture of printed circuit board uses integrated printed circuit board technology to realize the highly integrated combination of resistors, capacitors and other separate electronic components. Form a systematic function in the manufacture of printed circuit boards. On the one hand, it can effectively reduce the input cost and make it more environmentally friendly. On the other hand, it effectively improves the system functional stability of electronic equipment, and the signal transmission speed is faster. Integrated printed circuit board technology has actively promoted the development of printed circuit board manufacturing to light, thin, short and small. Constitute an integrated system, micro-electronic equipment, and further open up the electronic equipment market.

2. Rigid-flex technology.

The manufacturing of the printed circuit board uses the rigid and flexible printed circuit board technology to realize the layer-by-layer and multi-layer structure of the printed circuit board. On the one hand, it promotes the small and lightweight manufacturing of electronic equipment, which makes it more convenient to carry. On the other hand, the cycle of function and performance is improved, and the design is more optimized. The use of rigid and flexible printed circuit board technology, in the limited chassis space, to maximize the utilization rate. The small laminated multilayer board and cable are combined to form a systematic structure, that is, the analog rigid-flex printed circuit board. On the one hand, it effectively saves the chassis space, on the other hand, it effectively realizes the integrated functional system structure. At present, the rigid and flexible printed circuit board technology is widely used in the development and design of mobile devices.

3. Laser direct imaging technology.

Laser direct imaging technology is widely used in the pattern transfer link in the manufacturing process of printed circuit board. The operation principle of laser direct imaging technology is mainly to use blue light or ultraviolet light to focus the laser, scan the raster, digitize the graphics, control the laser imaging through the data, and expose one laser point at a time. Gradually form a pattern. It is not necessary to use the film needed in the traditional imaging process. On the one hand, it greatly improves the stability of imaging. On the other hand, it effectively optimizes the imaging process. At the same time, the cost is effectively controlled and the manufacturing efficiency is improved.

4. High heat dissipation technology.

The manufacture of the printed circuit board uses the printed circuit board technology with high heat dissipation to achieve low loss and high heat dissipation of the printed circuit board. With the help of the good thermal conductivity of metal materials, the heat generated by the work done by various components in the printed circuit board can be derived efficiently. On the one hand, it can effectively improve the reliability of component packaging and effectively control the volume. On the other hand, the cost of assembly is greatly reduced, and the rigidity of the printed circuit board is effectively improved. The printed circuit board with high heat dissipation introduces the partially implanted metal block printed board, which is more advanced and optimized in the concept of heat dissipation design. It has a good prospect for development.

In theory, the new type of high heat dissipation printed circuit board, first of all, the local implantation of metal block printed circuit board due to the particularity of the design, the heat dissipation performance is more perfect, through the printed circuit board components in direct contact with the heat dissipation block, simplifies the heat dissipation path. Secondly, the design of locally implanted metal block PCB is more flexible, which can not only achieve the heat dissipation requirements of all large components in the printed circuit board, but also achieve the heat dissipation requirements of designated large components. The mode of operation is more flexible, and the means of heat dissipation are more meticulous. The local implantation of metal block PCB is a kind of embedded heat dissipation design, and the embedded heat dissipation block is almost coplanar with the printed circuit board, so it will not interfere with the surface mounting work of the printed circuit board. Finally, the local implantation of metal block PCB further promotes the development of PCB manufacturing in the mainstream direction of light, thin, short and small.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider