Wondering why China is the go-to for electronic assembly? This guide explains China’s cost benefits, technological edge, and the top companies in the China electronic assembly sector to consider.

Key Takeaways

-

China’s electronics manufacturing industry is a global leader, generating £2.7 trillion in revenue and producing around 70% of the world’s smartphones and 60% of laptops, supported by Special Economic Zones and government policies.

-

Chinese PCB assembly companies like Viasion Technology and Shenzhen Kaifa Technology are recognized for their innovation and quality, with advanced manufacturing processes that include surface mount technology and comprehensive quality assurance measures.

-

The future of China’s electronics assembly industry is poised for growth, influenced by government initiatives focusing on self-reliance in semiconductor production and the adoption of emerging technologies like 6G and quantum computing.

China's Electronics Manufacturing Industry

China electronic manufacturing industry is a behemoth, generating a staggering £2.7 trillion in revenue in 2024, the highest globally. This colossal industry produces approximately 70% of the world’s smartphones and 60% of laptops, underscoring its pivotal role in global supply chains. But what makes China the go-to destination for electronics manufacturing?

Several factors contribute to the growth and dominance of China’s electronics manufacturing industry:

-

Special Economic Zones (SEZs) have been instrumental in attracting foreign investment and fostering technological growth.

-

These zones offer favorable policies, subsidies, and well-developed infrastructure, creating an ecosystem ripe for innovation and mass production.

-

The Chinese government has shown unwavering support through policies aimed at enhancing domestic semiconductor production, ensuring the industry’s sustained growth.

However, the landscape is not without its challenges. Rising labor costs are beginning to erode China’s long-standing cost advantages in electronics manufacturing. Despite this, the domestic market remains robust, characterized by a high demand for advanced electronics, including AI and IoT devices. This increasing demand continues to drive the evolution of the electronics sector in China.

The Greater Bay Area (GBA) has emerged as a key innovation hub, integrating technology and manufacturing across nine cities. This region exemplifies how China is not just a manufacturing giant but also a center for technological advancements. Skilled labor, extensive supply chain networks, and government support collectively contribute to the industry’s growth. With such a dynamic environment, China’s electronics manufacturing industry is poised for continued success.

Leading PCB Assembly Companies in China

Leading the charge in China PCB assembly industry are companies like Viasion Technology, Shenzhen Kaifa Technology, and ALLPCB, a notable pcba manufacturer. These companies are recognized for their quality, innovation, and commitment to excellence. Viasion Technology, for instance, is renowned for its dedication to quality, holding ISO 9001 and ISO 14001 certifications and offering complete PCB assembly services. Such certifications ensure that the highest standards are maintained throughout the assembly process.

Shenzhen Kaifa Technology stands out for its innovative technology approach and commitment to producing high-quality products across various sectors. Their technological advancements have made significant contributions to the electronics manufacturing industry, particularly in providing efficient PCB assembly solutions.

ALLPCB, on the other hand, is recognized for its innovative assembly approach and efficiency in PCB assembly processes, ensuring quick turnaround times without compromising on quality in pcb boards.

Companies like Avary Holding and Kinwong Electronics also play crucial roles, serving diverse industries, including telecommunications, automotive, and consumer electronics. The collective impact of these companies is significant, enhancing China’s standing in global PCB assembly through continuous advancements and adherence to stringent quality standards. Their contributions underscore why China remains a leader in the PCB assembly industry.

PCB Assembly Process in China

The PCB assembly process in China is a meticulously structured workflow designed to ensure the highest quality and efficiency. It includes the following steps:

-

Project file review and engineering assessment

-

Material sourcing

-

Assembly

-

Inspection for the pcb assembly project

This comprehensive approach ensures that each step is executed with precision, from the initial design to the final product.

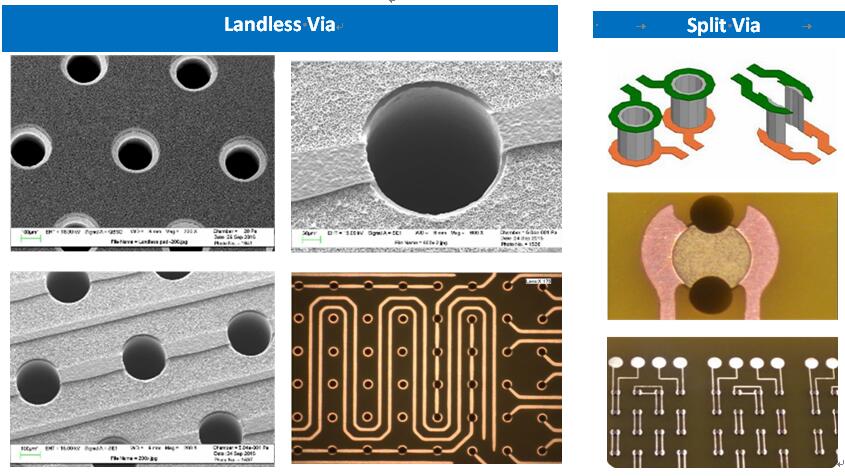

Chinese manufacturers are adept at handling various PCB types, including rigid, flexible, and hybrid designs, catering to a wide range of applications. Surface mount technology (SMT) plays a crucial role in this process, allowing for a high density of components on PCBs through automated processes. This technology ensures efficient assembly and is often complemented by through hole technology (THT), which involves inserting component leads into the PCB and using wave soldering for strong mechanical support.

Mixed technology assembly is also prevalent, combining both SMT assembly and THT components on a single PCB to optimize performance and space efficiency. Quality control measures are integrated throughout the assembly process, including testing and inspection, to ensure that the final product meets the highest standards. By sourcing components directly from authorized distributors, Chinese manufacturers ensure authenticity and reliability, further enhancing the quality of the PCB assemblies. Additionally, tht assembly plays a crucial role in this optimization.

Turnkey PCB Assembly Services

Turnkey PCBA services offer a comprehensive solution that includes turnkey services:

-

PCB fabrication

-

Component sourcing

-

Assembly

-

Testing

-

Final shipment

-

PCB assembly service

-

PCBA solutions

This all-inclusive approach ensures that customers receive a finished product without the hassle of coordinating multiple suppliers and service providers. It is particularly beneficial for companies looking to streamline their production lines and minimize potential errors.

Full turnkey PCB assembly services typically include:

-

PCB fabrication

-

Sourcing of components

-

Order tracking

-

Quality monitoring

-

Final assembly

-

Testing

-

PCBA services

Collaboration with customers is key, as manufacturers work closely with them to mitigate issues, shorten lead times, and ensure the highest quality standards are met. This collaborative approach helps in addressing any concerns promptly and effectively.

To ensure timely delivery, manufacturers often assist with logistical arrangements through partnerships with leading delivery agencies, aiming for quick turnaround times. This logistical support is crucial in today’s fast-paced market, where timely delivery can make a significant difference in meeting customer expectations and staying competitive.

Advanced Technologies in PCB Assembly

Advanced technologies are revolutionizing the PCB assembly industry, enhancing precision, efficiency, and overall quality. Automated optical inspection (AOI) is one such technology, crucial for identifying defects before and after the soldering process, ensuring components are placed correctly. This automated approach significantly reduces the likelihood of errors, contributing to the production of high-quality PCB assemblies.

X-ray inspection is another advanced technology used to assess the integrity of solder joints and internal structures of PCBs that are not visible from the surface. This adds an extra layer of quality assurance, ensuring that even the most complex assemblies meet stringent standards.

Wave soldering is also employed, allowing for the soldering of multiple components simultaneously by passing the PCB over a wave of molten solder.

Investment in automation and high-value technologies, including AI, remains robust, indicating a continual commitment to innovation in the PCB assembly sector in China. These advancements help reduce costs while maintaining high-quality manufacturing standards. The integration of such technologies is transforming the PCB assembly process, making it more efficient and precise.

Quality Assurance in PCB Assembly

Quality assurance is a cornerstone of the PCB assembly process, ensuring that the final products meet the highest standards of reliability and performance. Multiple inspections are conducted at various stages, including solder paste and final product testing, to maintain quality control in PCB SMT assembly. Full testing suites like In-Circuit Testing (ICT), Functional Testing (FCT), and aging tests are employed to ensure the reliability of the assembled PCBs.

Material quality assurance is enforced through the inspection of LCR parameters and IC chip quality, ensuring long-term performance. Automated testing is integrated at multiple stages of the PCB assembly process, contributing to high-quality outcomes. This rigorous approach to quality control is vital in producing high-quality products that meet the demands of various electronic applications.

Certified IPC trainers are often employed to ensure that staff are knowledgeable about quality standards and practices in PCB production. Manufacturers with ISO 9001 certification adhere to international quality management standards, providing an additional layer of confidence in their products. Proper packaging of PCBs is also crucial for maintaining quality during transport, reflecting the manufacturer’s commitment to product integrity.

Cost-Effective PCB Assembly Solutions

China PCB manufacturing industry benefits significantly from large-scale production, leading to lower prices for assembly services. This scale allows manufacturers to offer competitive pricing while maintaining high standards of quality. Efficient supply chains further reduce the overall pcb assembly cost, making it an attractive option for businesses worldwide in the realm of pcba manufacturing.

Rapid production cycles enhance cost-effectiveness by ensuring quicker turnaround times. This efficiency is crucial in meeting market demands and staying competitive. Additionally, sourcing components at lower prices in China contributes to the affordability of PCB assembly services.

These low cost solutions make China a preferred destination for PCB assembly.

Environmental Sustainability in PCB Assembly

Environmental sustainability is becoming a priority for Chinese PCB assembly company. They are increasingly utilizing lead-free soldering and water-based fluxes to minimize hazardous waste and pollution. Using eco-friendly materials, such as halogen-free laminates and biodegradable polymers, enhances the recyclability of PCBs. These practices reflect a commitment to reducing the environmental impact of PCB manufacturing.

Waste reduction strategies, including reusing components and optimizing raw materials, help decrease landfill waste. Many manufacturers are also investing in renewable energy sources like solar and wind to cut down their carbon emissions. Establishing sustainable components sourcing criteria and conducting supplier audits ensure that companies adhere to environmental standards.

Adopting circular economy principles encourages designs that promote product longevity and reduce electronic waste. These efforts highlight the growing importance of environmental sustainability in the PCB assembly industry in China, focusing on practices that minimize ecological impact.

Industries Served by Chinese PCB Assemblers

China PCB assemblers serve a wide range of industries, including:

-

Consumer electronics

-

Automotive

-

Medical devices

-

Telecommunications

-

Industrial control

-

Renewable energy

Companies like WT Microelectronics, Hollison Electronics, and Agile Circuit provide efficient PCB assembly solutions for the consumer electronics industry. Their contributions ensure that everyday electronic products are reliable and high-quality.

The automotive industry benefits from PCB assembly services provided by companies like Viasion Technology and Shenzhen Kaifa Technology. These services are crucial for the production of advanced automotive electronics, ensuring safety and performance.

The medical devices and telecommunications sectors also rely on high-quality PCB assemblies from companies like Rayming Technology. Industrial control systems, including renewable energy solutions, benefit from PCB assembly services, emphasizing the wide range of applications such as:

-

Medical devices

-

Telecommunications

-

Industrial control systems

-

Renewable energy solutions

This diversity showcases the versatility and capability of Chinese PCB assemblers in meeting the demands of various industries.

Choosing the Right PCB Assembly Partner in China

Selecting the right PCB assembly partner in China is crucial for ensuring quality and reliability. Look for a company with a minimum of five years of relevant industry experience. This experience indicates a proven track record and expertise in handling complex PCB assembly projects. Evaluate the technological capabilities of the partner to confirm they can handle the specific types of PCB fabrication needed for your project.

When selecting a PCB assembly partner, consider the following:

-

Skilled workers who are knowledgeable and well-trained to maintain high standards in PCB manufacturing.

-

Excellent customer service, regardless of order size.

-

Timely and accurate updates provided throughout the production process.

Key considerations include:

-

Discuss budget considerations upfront, including potential discounts for bulk orders, to align expectations with pricing.

-

Ensure fast turnaround times to enhance production efficiency and respond quickly to market demands.

-

Prioritize security and confidentiality measures to protect your intellectual property and sensitive project information.

Case Studies of Successful PCB Assembly Projects

Examining case studies of successful PCB assembly projects reveals the advanced capabilities and high standards maintained by Chinese manufacturers. One notable example is a medical device manufacturer achieving a zero-defect assembly of a complex PCB assemblies 14-layer rigid-flex PCB, delivered in just 10 days for clinical testing. This project underscores the precision and efficiency of Chinese PCB assemblers in meeting stringent quality requirements and tight deadlines, particularly in prototype pcb assembly.

In another case, a large-format LED lighting panel project required custom equipment modifications to ensure precise color consistency across 500+ units produced monthly. The ability to handle such complex requirements and maintain high-quality standards highlights the expertise and adaptability of Chinese PCB assembly companies.

These successful projects emphasize the advanced capabilities of Chinese manufacturers in delivering high-quality products under complex requirements. The expertise demonstrated in these projects showcases the ability to meet intricate industry demands and maintain quality standards, reinforcing why China remains a leader in the PCB assembly industry.

Future Trends in China's Electronics Assembly Industry

The future of China’s electronics assembly industry looks promising, driven by strategic initiatives and technological advancements. The Chinese government’s Five-Year Plans prioritize technology and electronics as essential for economic growth, focusing on self-reliance in semiconductor production to mitigate global supply chain disruptions. These initiatives ensure that China remains at the forefront of the global electronics industry.

Export recovery is anticipated as global demand stabilizes, although geopolitical issues and trade restrictions may pose challenges. Addressing these challenges requires policies that support industrial upgrades and help manage regional disparities in growth. Despite these hurdles, the industry is expected to continue growing, driven by innovations like 6G, quantum computing, and renewable energy.

These future trends indicate sustained growth and ongoing innovation in China’s electronics manufacturing industry. By embracing new technologies and strategic initiatives, China is well-positioned to maintain its leadership in the global electronics assembly sector.

Recommend the Leading China Electronic Assembly Manufacturer - Topscom

Topscom Group stands out as a leading China PCB manufacturer, specializing in advanced printed circuit board assembly. With over 15 years of experience, Topscom has established itself as a top-tier manufacturer, ranking among the top 20 in China. The company offers an extensive range of high-tech prototypes, including HDI boards, multilayer boards (up to 70 layers), and rigid-flex boards. Their expertise in advanced PCB fabrication and assembly makes them a preferred choice for high-end, high-complexity projects, particularly in the realm of pcb board production.

Topscom’s commitment to superior quality and innovation is evident in their in-house qualification of advanced laminate materials, signal integrity analysis, and DFx. By working closely with global customers to develop advanced PCBs with unique requirements, Topscom ensures that they meet the highest standards of reliability and performance. Their comprehensive electronics manufacturing services reinforce their position as a leading player in the industry.

Summary

In summary, China’s electronics assembly industry is a dynamic and vital part of the global supply chain. From leading PCB assembly companies and advanced manufacturing processes to comprehensive turnkey services and stringent quality assurance measures, the industry exemplifies excellence and innovation. Cost-effective solutions and a commitment to environmental sustainability further enhance China’s position as a leader in the field.

As we look to the future, strategic initiatives and technological advancements will continue to drive growth and innovation in China’s electronics assembly industry. For those seeking a reliable and high-quality PCB assembly partner, Topscom stands out as a leading manufacturer, offering advanced capabilities and extensive experience. By choosing the right partner, businesses can ensure the success of their PCB assembly projects and stay competitive in the global market.

Frequently Asked Questions

What factors contribute to the growth of China's electronics manufacturing industry?

The growth of China's electronics manufacturing industry is significantly driven by strong government support through favorable policies, subsidies, and infrastructure development, alongside the establishment of Special Economic Zones (SEZs) and the innovative environment of the Greater Bay Area (GBA). These elements collectively create an enabling ecosystem for the industry to flourish.

What are the benefits of turnkey PCB assembly services?

Turnkey PCB assembly services provide a complete package that enhances efficiency and reduces errors by integrating all processes—from fabrication to final shipment—while ensuring timely delivery. This holistic approach allows companies to focus on their core business while benefiting from streamlined operations.

How do advanced technologies enhance PCB assembly?

Advanced technologies such as automated optical inspection (AOI), X-ray inspection, and wave soldering significantly enhance precision, efficiency, and quality in PCB assembly. These innovations reduce costs and ensure adherence to high standards in manufacturing.

What industries benefit from Chinese PCB assembly services?

Chinese PCB assembly services benefit industries such as consumer electronics, automotive, medical devices, telecommunications, industrial control, and renewable energy. These sectors rely on efficient and cost-effective PCB assembly for their technological needs.

What should I consider when choosing a PCB assembly partner in China?

When selecting a PCB assembly partner in China, it is essential to consider their industry experience, technological capabilities, and communication practices. Additionally, aspects such as skilled workforce, customer service, budget alignment, turnaround times, and security measures should also be evaluated to ensure a successful partnership.