What is the PCB and PCBA and What is the Difference Between Them?

I believe that many people are familiar with the terms related to the electronic industry, such as PCB board and SMT chip processing, which are often heard in daily life, but many people do not know much about PCBA and are often confused with PCB. So what is PCBA? What is the difference between PCBA and PCB? Let's learn about it.

What is PCB and PCBA:

Introduction to PCBA:

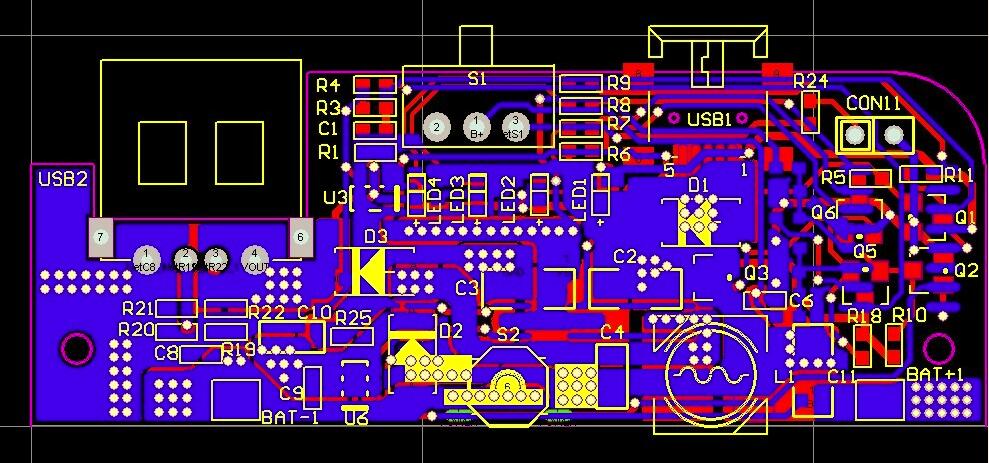

PCBA process: PCBA=Printed Circuit Board Assembly, means that the PCB empty board goes through the SMT part, and then through the whole process of the DIP plug-in, referred to as the PCBA process.

Introduction to PCB:

PCB, also known as PCB board or printed circuit board, is an important electronic component, is the support of electronic components, is the carrier of electrical connection of electronic components. Because it is made by electronic printing, it is called a "printed" circuit board. Printed circuit board often used the acronym PCB (Printed circuit board) or PWB (Printed wire board), is an important electronic component, is the support of electronic components, is the circuit connection provider of electronic components. The traditional circuit board uses the method of printing etching resistor to make the circuit and drawing of the circuit, so it is called printed circuit board or printed circuit board. Due to the continuous miniaturization and refinement of electronic products, at present, most circuit boards use etching resistors (pressure film or coating), after exposure and development, and then etch to make the circuit board.

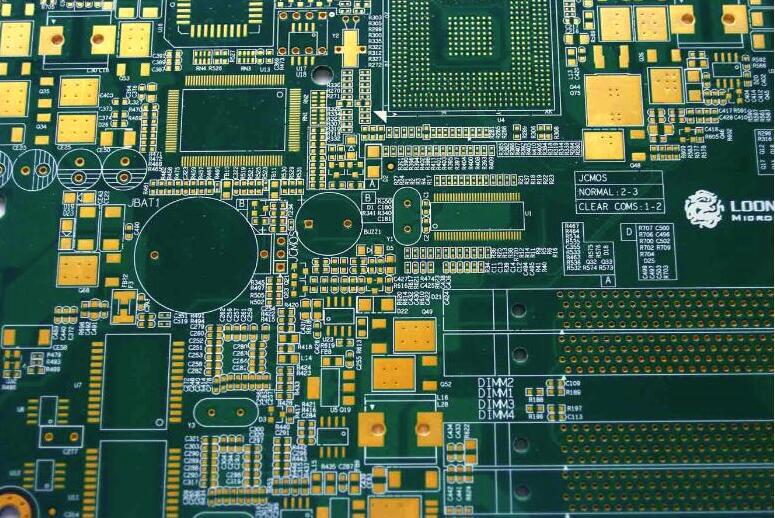

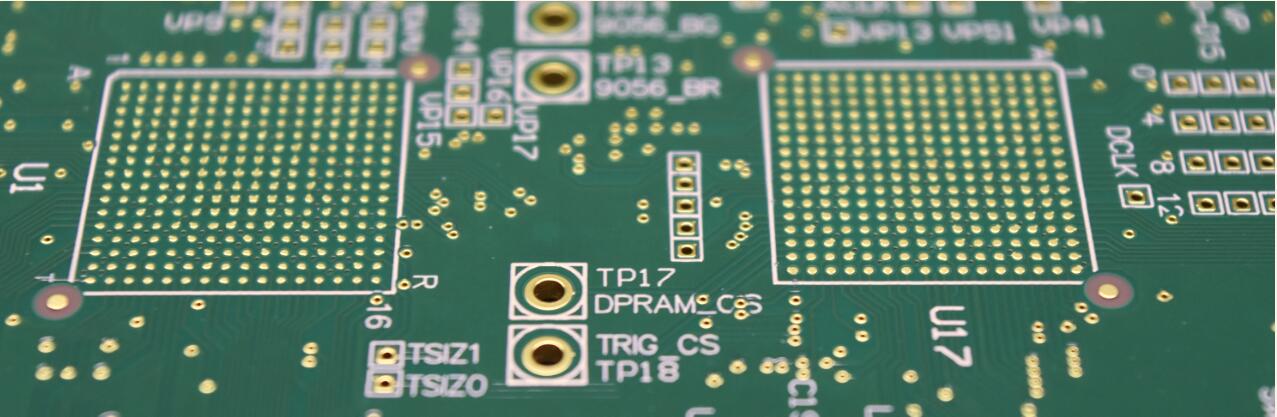

Technical practicality. In the late 1990s when a large number of layering printed circuit board schemes were proposed, incremental printed circuit boards were officially put into practice in large quantities until now. It is important to develop a robust testing strategy for large, high-density printed circuit board assembly (PCBA, printed circuit board assembly) to ensure compliance and functionality with the design. In addition to the establishment and testing of these complex assemblies, the money invested in electronic components alone can be high-up to $25000 when a unit is finally tested. Because of such high costs, the problem of finding and repairing assembly is now an even more important step than it used to be. Today's more complex assembly is about 18 square inches and 18 layers; there are more than 2900 components on the top and bottom; 6000 circuit nodes; and more than 20000 solder joints need to be tested.

What is the Difference Between PCB and PCBA?

1.PCB does not have any components.

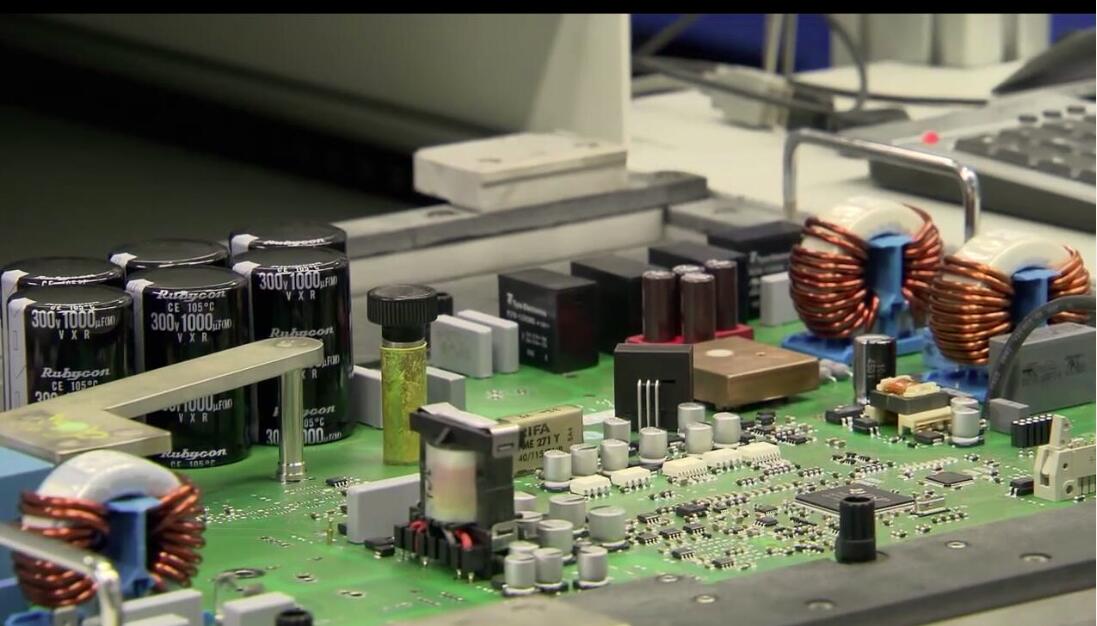

2.PCBA is the electronic components that manufacturers need to weld and assemble on the PCB board through SMT or plug-in processing after getting the PCB as the raw material, such as IC, resistors, capacitors, crystal oscillators, transformers and other electronic components, after high temperature reflow furnace heating, the mechanical connection between the components and the PCB board will be formed, thus forming PCBA.

From the above introduction, we can know that PCBA generally refers to a processing process, can also be understood as a finished circuit board, that is, the process on the PCB board has been completed before it can be counted as PCBA. PCB, on the other hand, refers to an empty printed circuit board with no parts on it.

With the ultra-miniaturization of electronic machines with high speed and high performance, packaging technology has made great progress. Chip size packaging CSP and BGA packaging are developing in the direction of multi-lead terminals and narrow lead spacing, and bare chip (Bare Chip) packaging has also been practical. Due to the progress of these packaging technologies, new requirements for printed circuit boards (PCB (Printed Wiring Board)) are also put forward (to meet the needs of high-density packaging and high-speed).

Before the electronic products manufacturers, to complete a complete circuit board production, usually need to purchase PCB back, and then contact the chip manufacturers, processing, the process is very troublesome, cost a lot of cost. Nowadays, many manufacturers are willing to choose China PCB manufacturer to process patches at the same time in the production of PCB, or to let patch manufacturers replace the procurement of PCB, both of which save a lot of trouble and speed up production efficiency. And PCBA manufacturers can achieve these two fast and effective processing methods.

PCB procurement and chip processing are two different production methods, and many electronic manufacturers only specialize in one of them, which requires electronic products manufacturers to comprehensively consider the strength of manufacturers and choose experienced manufacturers who can excellently complete the whole processing process when choosing PCBA processing manufacturers.

The development of high-density interconnection technology (HDI) interconnection HDI embodies the most advanced technology of contemporary PCB, which brings fine wiring and micro-aperture to PCB.

Component embedding technology with strong vitality component embedding technology is a great change in PCB functional integrated circuits. PCB manufacturers need to increase resource investment in systems including design, equipment, testing and simulation in order to maintain strong vitality.

PCB materials in line with international standards have high heat resistance, high glass transition temperature (Tg), low thermal expansion coefficient and small medium constant.

Optoelectronic PCB has a broad prospect. It uses the optical path layer and the circuit layer to transmit signals. The key of this new technology is to make the optical path layer (optical waveguide layer). It is a kind of organic polymer, which is formed by lithography, laser ablation, reactive ion etching and so on.

Update PCB Board Manufacturing Process And Introduce Advanced Production Equipment

Folding industry transfer.

With the improvement of global awareness of environmental protection, energy conservation and emission reduction has become an urgent task for the development of countries and enterprises. As a high emission rate of pollutants, PCB board enterprises should be more important responders and participants in the work of energy saving and emission reduction.

In the manufacture of PCB prepreg embryos, microwave technology is developed to reduce the use of solvents and energy.

Develop new resin systems, such as water-based epoxy materials, reduce the harm of solvents, extract resins from renewable resources such as plants or microorganisms, and reduce the use of oil-based resins.

Looking for materials that can replace lead-containing solders.

Develop new, reusable sealing materials to ensure recyclable devices and packages and ensure removable.

Folding technology improvement.

The precision of PCB reduces the size, width and spatial orbit of PCB.

The durability of PCB board is in line with international standards.

PCB's High performance Impedance reduction and improvement of Blind buried Hole Technology.

Advanced production equipment imports production equipment from Japan, the United States, Taiwan and Europe, such as automatic electroplating line, gold plating line, machinery and laser drilling machine, large press, automatic optical inspection, laser plotter and circuit testing equipment, etc.

The quality of human resources includes technical and management personnel.

Environmental pollution treatment meets the requirements of environmental protection and sustainable development.