Application case study of Intelligent Manufacturing IMS systems in Automotive vehicle electronic device Industry pcb assembly and turnkey contract electronic manufacturing service.

Today's vehicle and parts manufacturers are facing great challenges: low production efficiency; high labor costs and difficulties in recruiting employees; ERP can not be connected to manufacturing; there are often major quality accidents of wrong materials; comprehensive traceability management cannot be achieved; high on-site inventory remains high.

China's auto industry has risen to the second largest car output in the world. In the next five years, the size of China's car market is likely to surpass that of Japan's. With the rapid growth of the domestic automobile market, China's automobile industry is facing many challenges, such as the rise of raw material costs, the promotion of labor costs, and the price pressure of the same industry enterprises. if the domestic automobile industry wants to achieve large-scale expansion and personalized marketing, the realization of intelligent workshop management is bound to become the core competitive advantage. the article is posted by Ms.Lee yanxia, Director of Topscom Automotive EMS Project Department,China Topscom provide professional Pcb boards layout design,pcb assembly and manufacturing,full turnkey systems integration box build assembly,contract electronic manufacturing service.

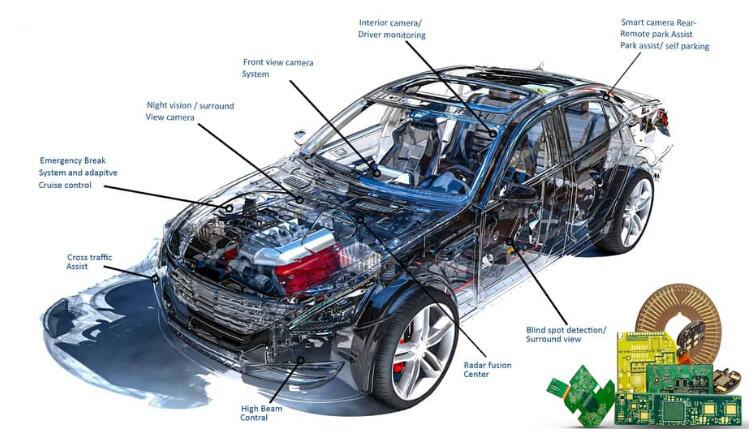

With the great increase of the application proportion of electronic components in automotive products, the continuous occurrence of recalls, and quality problems have been affecting the revenue and profits of automobile manufacturers, a set of perfect production management and traceability system has become the urgent demand of automotive electronics manufacturers.

Will there be a "car bubble" in China in the next five years?

The auto industry has always been one of the biggest buyers of ERP systems in China. The ERP process of domestic automobile industry started in the 1990s. In 2001, Shanghai invested 100 million yuan to establish Shanghai Automotive Information Industry Investment Co., Ltd. Shanghai General Motors Co., Ltd. Alone invested more than US $80 million in the construction of information management systems at that time.

Up to now, the overall information level of some large automobile factories (especially Sino-foreign joint ventures) has reached a high level, and the traditional ERP also has a considerable popularization rate. Among them, complete vehicle enterprises such as FAW-Volkswagen, Shanghai Volkswagen, Shanghai General Motors, Changan Automobile and Jiangling Group have performed particularly well in this regard. However, at present, the informationization of the domestic automobile industry does not give full play to its function of improving the overall efficiency of the industry-the independent ERP system in a separate enterprise can meet the daily management functions within the enterprise, but it can not really effectively connect with the manufacturing and understand the real-time production situation, which is the top priority for the automobile industry to improve efficiency.

At the same time, more and more new entrants to the automobile industry are very lack of related information applications. The development of the industry in China is not like most people imagine, information, standardization and intelligent applications have been put on the agenda.

The development of China's automobile industry is very irregular, and some people in the industry predict that there will be a "car bubble" in China in the next five years. A large number of new enterprises will fail. On the one hand, this sense of crisis gives birth to the demand for informatization in the automobile industry, on the other hand, it also forces China's automobile industry to implement a scientific and reasonable production plan. All these doomed that the management mode of Chinese automobile enterprises will be changeable, which also brings great difficulty to its information construction. At the same time, as there will be bankruptcy or restructuring, acquisition, at the beginning of the construction of many automobile enterprises, it is best to consider the integration of different systems that may occur in the future. the article is posted by Ms.Lee yanxia, Director of Topscom Automotive EMS Project Department,China Topscom provide professional Pcb boards layout design,pcb assembly and manufacturing,full turnkey systems integration box build assembly,contract electronic manufacturing service.

What kind of standards can be achieved in automobile production and manufacturing?

Intelligent production scheduling.

JIT pull material supply.

Material prevention and error correction in the whole process.

Full process control (SMT, DIP, pcb boards assembly).

Quick mold change for SMED.

"Real-time electronic billboards.

Red card management.

Comprehensive repair management.

Statistical analysis of SPC.

Guard against stagnation in the working procedure.

"Shipping anti-dumb management,"

In terms of materials, which material codes, suppliers, production cycles, batches can be traced back to ….

From the perspective of products, trace products, orders, shipping batches, customers.

From the perspective of quality, which BOM, ECN and programs can be traced back?

Automobile recalls occur frequently, so it is inevitable to strengthen traceability management, and quality, cost, delivery and efficiency have become major issues.

In the automotive industry, traditional business models are shifting to a transparent, customer-oriented value chain, and success depends on many aspects, including the speed of product development, the speed of assembly, the speed of delivery, and the speed of response to dealers and customer service.

How to strengthen the management and control of each production link.

1. Manpower improvement.

AOS automatic feeding, cancel manual check of materials and quantities and other operations, automatically generate IQC inspection report.

Through the LPM low-level alarm operation, realize the warehouse JIT direct feed production line, cancel the line side warehouse, cancel the production line station box storage and personnel hand-in operation.

Strengthen error prevention, cancel manual confirmation of material number or specification description, check station position, etc., cancel first piece confirmation and IPQC review.

The equipment is online, real-time monitoring production line production data, all KPI reports, no manual statistics to fill in, all automatically generated by the system.

Mobile terminal equipment can query the production attributes of materials (material number, work order number, line, station, demand quantity, remaining quantity, etc.) anytime and anywhere.

Intelligent conversion, inventory plan and perfect location management can greatly optimize the warehouse workload and operation efficiency.

2.. Incoming material inventory management.

There is an ISO sampling standard, and the sampling quantity is generated automatically.

There is no need for manual handwriting to send the inspection form.

Materials are managed by Reel ID and automatically acquired by AOS.

Check raw material information, check material information and quantity automatically.

There is no need for handwritten inspection forms and manual confirmation of work.

The inspection result of IQC automatically assigns the Reel ID attribute to the material.

The whole process of anti-stupor management and control, automatically generate IQC inspection report.

Seamless connection with ERP to update account value automatically.

3. Warehouse management.

Materials will automatically collect the original material volume label information, material Reel ID information upload system, all the information of the material can be checked at any time, there is no need for multiple point-to-point and handwritten records to cause data waste.

Cancel the management of online silos through informationization.

Automatically record the incoming date of materials and follow up and manage them according to the principle of FIFO.

Record the location information of all materials in the warehouse, optimize the order of material preparation, and improve the efficiency of personnel operation.

JIT material delivery is implemented according to the requirements of the production line, and the material separation function makes the work easier.

Record the usage status of all materials, complete the work order, automatically generate the work order loss list, and realize the work order inventory.

Materials can automatically distinguish different types of materials, background classification management, automatic processing of ERP account value.

4.SMT production line management.

The warehouse staff will send the material directly to the production line and cancel the transfer to the point-to-point operation in each link.

Analyze the work order, obtain the material status of the work order, and import it into ECN automatically.

The material is prompted by the mobile terminal to prepare the material, and the properties of the material can be obtained by scanning the Reel ID, which ensures the correct distribution of the material and automatically enters the deduction of the system.

According to the delivery mode of equipment program + BOM, Reel ID not only has material properties but also contains production properties.

The low-level alarm of LPM can keep abreast of the use of materials in the production line and prepare materials as needed. the article is posted by Ms.Lee yanxia, Director of Topscom Automotive EMS Project Department,China Topscom provide professional Pcb boards layout design,pcb assembly and manufacturing,full turnkey systems integration box build assembly,contract electronic manufacturing service.

"all production process systems have corresponding operation records, and no paper file reports are required.

No need for IPQC cross-check.

5. Electronic Kanban management.

Using MDC technology to automatically collect original information and make statistical analysis.

Target management, uncontrolled conditions are triggered automatically, and early warning management is realized through SMS and email feedback.

Monitor the operation status of the equipment in real time, and count its operation data, so as to facilitate the optimization of wire-body balance.

All KPI reports and related records are directly generated by the system.

Complete paperless work.

In order to really realize the road of intelligent manufacturing, it is necessary to realize intelligent control in the whole process from incoming materials to the delivery of finished products. Fortunately, the modern intelligent technology IMS system can fully realize this dream, and what is more surprising is that the realization of this process management will not bring additional costs to the factory. On the contrary, it can save more than one million manufacturing costs every year.

The factory will enhance the core competitiveness of enterprises in all aspects such as quality management, production management and equipment management, not only in the automobile manufacturing industry, but also in all electronic manufacturing industries. In the future, it will become easier to audit the quality management system of customers of the world's top companies, and enterprises can also get more orders and more profits. At present, less than 5% of enterprises have this competitiveness, and the prospect is infinitely broad!

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider