China Topscom posted a article on china electronics PCB magzine about In terms of PCB boards manufacturing and assembly, is Industrial 4.0 really revolutionary?

What's the first thing that comes to mind when someone says revolution? Change, not forever. Something that changes the way of life. In most cases, the changes shown must be made. Industries in the economic sector related to commodity manufacturing have also undergone several revolutions. The time when we invested money was the fourth Industrial Revolution or what we call Industrial 4.0.

The first industrial revolution was mechanized by water and steam power. Then there is the second power production and assembly line. The fourth industrial revolution will begin with the third adoption of computers and automation. Further, it is enhanced by intelligent autonomous systems driven by data and machine learning.

So, what kind of industry 4.0 is this?

We have read a lot about the envisaged technical framework for implementing Industrial 4.0. This will completely reschedule the legacy of the production process. The revolution will witness a shift from an analog centralized workflow to a digital decentralized production process. The ultimate goal of all this digitization is to create self-directed or autonomous production processes. Customer orders can obviously promote their own development throughout the supply chain and manufacturing process with little or no human intervention. This new framework will lead to breakthroughs in production efficiency, increase overall production and significantly reduce production costs.

But the revolution is still in its infancy. Therefore, it is not really reasonable to define all its properties. It is still vague to measure the extent of change, or the extent to which it will change an industry or economic landscape. Even if some people regard Industrial 4.0 as just a marketing buzzword, changes in manufacturing are taking place and deserve our attention.

What are the main attributes of Industry 4.0?

Industrial Internet of things-well, as the name suggests, it is the Industrial Internet of things. Or in layman's terms, it is the IoT structure in industrial facilities, where machines communicate with each other and exchange data, and exchange data with other system devices.

Automated robots-machines that interact with each other will upgrade the aspects in which they work independently in a given ecosystem.

Cloud-Cloud will achieve the same goal as IoT, which will store, transfer or share data whenever and wherever it is needed.

Big data processing-all data must be open source so that big data can be accessed anytime, anywhere.

Augmented manufacturing-the market for custom devices and components is booming; investors to customers, people are playing games around the idea.

Augmented reality (AR) and virtual reality (VR)-another exciting and interesting technology is VR and AR. They have the ability to simulate the process before the actual physical operation. Therefore, the downtime of the conversion is reduced.

These are a few very important attributes, and the list is not exhaustive!

PCB and Industry 4.0.

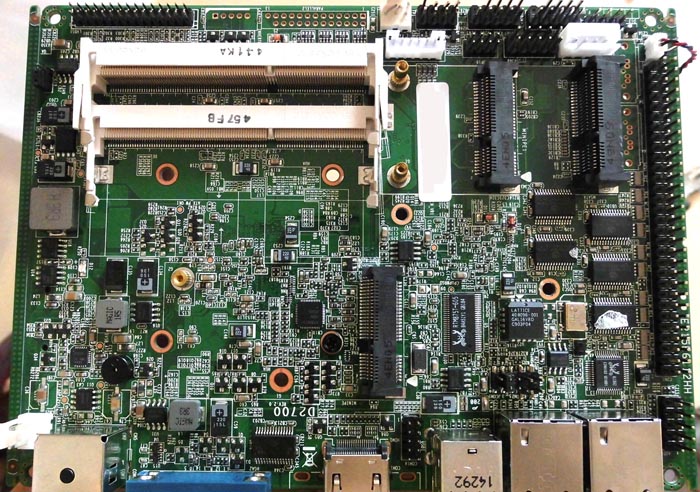

PCB production is widely regarded as a basic component of electronic equipment, which provides a good window for technological development. Industry 4.0. Interestingly, how big a role will PCB really play in strange marketing terms such as smart home, smart car and smart city?

In fact, PCB designers may be the hardest job when it comes to the Internet of things. On the one hand, there is a technology that is constantly evolving, and then all the advanced features are crammed with shrinking packaging sizes. Let's show you some (but not all) of the things you need to overcome! ) Challenge.

First, prepare to fight for each micron space in the layout. Gone are the days when there was extra layout space. But now, with the IoT device, it's not even the least needed space.

In addition, don't forget the time to design only the PCB and give it to your mechanical friends for installation check. In the world of the Internet of things, this workflow no longer works. With a smaller form factor, you will design the entire product, not just the PCB.

How's it going?

Well, be the best companion for your mechanical engineer. Because both you and your engineering team need to work at the same time. At every stage of the design process, modifications to mechanical components and circuit boards must be shared among disciplines in real time. Remember, you are no longer just designing circuit boards; you are designing circuit boards. You are developing products for a connected world.

When you think about these offsets, we make sure that Industrial 4.0 is not just a challenge. Let's make a detour and see what's the use.

People often find it difficult for PCB manufacturers to figure out from the huge amount of data pouring in from many sources. This is especially difficult when there are significant differences between the data attributes to be analyzed. With big data on the market, PCB manufacturers can extract the valuable data they need more quickly in order to make more informed decisions. Digital processes such as direct imaging, inspection, laser drilling and legend digital printing can accurately measure and check PCB panels at different production stages.

Moreover, real-time, high-precision inspection shortens the decision-making cycle and increases output. Re-tracking every step of manufacturing and PCB assembly can effectively reduce product recalls. Due to the high cost of recall and the need for a complete production process record, defective PCB, can be detected and isolated early, that is, they can be quarantined long before they are built into the final device.

Industry 4.0 is definitely a revolutionary approach to manufacturing technology.

This concept will push global manufacturers to a higher level of optimization and productivity. Not only that, but customers will also enjoy an unprecedented new level of customized products.

However, to ensure a smooth transition, there will be many challenges that need to be systematically addressed. Not only hard work, but also smart work will achieve Industrial 4.0.

Although speculation about privacy and security needs more research, the overall outlook is optimistic. Such a manufacturing approach is indeed revolutionary.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider