PCB SMT assembly chip processing detection methods include optical detection method, manual visual detection method and automatic optical detection method. How to select the chip inductor? The total width of the chip inductor should be lower than the total width of the inductor, and the allowable current is an index value of the chip inductor according to the large current; When welding or making patches by hand, you must be very careful and do not get the wrong parts or take the wrong parts. Let's introduce the PCB SMT assembly chip processing and testing method and how to select the chip inductance.

PCB SMT assembly patch processing and testing method:

1. Optical detection method

With the decrease of PCB SMT assembly chip component package size and the increase of PCB board chip density, SMA inspection is more and more difficult, and manual visual inspection is insufficient. Its stability and reliability are difficult to meet the needs of production and quality control, so the use of dynamic inspection is becoming more and more important.

2. Manual visual inspection method

This method needs less investment and does not need to develop the test program, but it is slow and subjective, and needs to visually observe the tested area. Due to the lack of visual inspection, it is rarely used as the main welding quality inspection means in the production line of PCB SMT assembly small batch patch processing plant, but mostly used for repair and rework.

3. Using automatic optical detection

As a tool to reduce defects, it can be used to find and eliminate errors in the early stage of patch processing, so as to achieve good process control. AOI adopts advanced visual system, new light supply mode, high magnification and complex processing methods to obtain high defect capture rate from the surface at high test speed.

How to select SMT inductor for PCB SMT assembly chip processing?

1. The total width of the chip inductor shall be lower than that of the inductor, so as to avoid excessive tensile stress caused by excessive welding materials during water cooling and change the inductor value.

2. The precision of most chip inductors that can be purchased in the sales market is ± 10%. If the specified precision is higher than ± 5%, it must be ordered in advance.

3. Some chip inductors can be welded by reflow furnace and wave soldering, but some chip inductors cannot be welded by wave soldering.

4. During maintenance, it is not allowed to replace the chip inductor with the inductor quantity alone. In order to ensure the operating characteristics, it is also necessary to understand the operating frequency band of the chip inductor.

5. The appearance design and specification basis of SMD inductors are similar, and the appearance design is not significantly marked. When welding or making patches by hand, you must be very careful and do not get the wrong parts or take the wrong parts.

6. At present, there are three kinds of chip inductors: first, high-frequency inductors for microwave heating. It is applicable to the application in the frequency band of about 1GHz. Second, high frequency chip inductor. It is suitable for series resonance control circuit and frequency selection power supply circuit. Third, practical inductors. It is generally applicable to tens of MHz power supply circuits.

7. Different commodities use different diameters of magnetic coils. Even if the same amount of inductor is used, the resistance measurement is different. In the high frequency control loop, resistance measurement is very harmful to Q value, so attention should be paid to the design scheme.

8. The allowable current is an index value of chip inductance according to the large current. When the power supply circuit must bear a large amount of current, this index value of capacitor must be considered.

9. When the power inductor is used in the DC / DC converter, its inductor size immediately endangers the working attitude of the power circuit. Combined with practice, the method of adjusting the magnetic coil can usually be selected to change the inductor quantity in order to achieve the best practical effect.

10. Winding inductors are common in communication equipment operating in the frequency range of 150-900mhz. In the frequency power supply circuit of about 1GHz, microwave heating high-frequency inductance must be used.

The above is a detailed introduction to the PCB SMT assembly chip processing and testing methods and how to select the chip inductor. If you have other problems, please continue to pay attention!

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

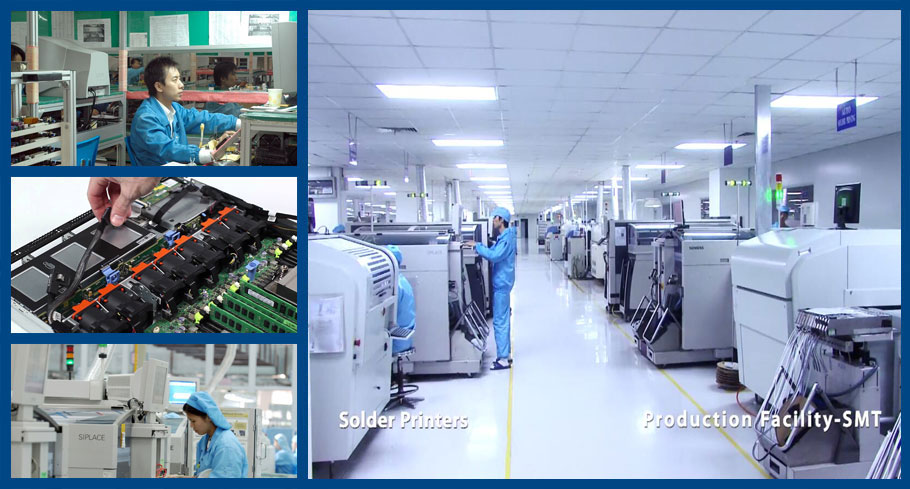

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider