What should manufacturers pay attention to when using PCBA foundry and what are their risks?

Now the China electronic manufacturing industry has a one-stop processing service that is gradually becoming popular, that is, the PCB Assembly OEM model. Today, the editor said, "What should manufacturers pay attention to when using PCBA foundry materials, and what risks does he have?"

1. What should manufacturers pay attention to when using PCBA foundry materials?

1) In the process of selecting a good OEM China PCB manufacturer, the customer must conduct a practical visit to its basic situation, especially the formality and professional ability of the manufacturer. Regarding its formality, we can learn from its corresponding qualification certificates, such as whether it is ISO9001 quality management system certification, etc.; it is necessary to be more careful to understand its professional capabilities in electronic product processing. For example, I personally went to the China printed circuit board assembly manufacturer to visit the site. The main contents of the visit include the situation of the PCB SMT assembly chip processing production workshop, the situation of the DIP production workshop, the office environment, the mental outlook of the employees, etc., for example, see if their machinery and equipment are Advanced enough, whether the PCB Assembly production process meets the regulations, whether the working environment of the production workshop is tidy, whether the materials are placed in an orderly manner, etc. Customers can also fully consider the development trajectory of the manufacturer in recent years. If the development is getting better, they can also judge the overall strength of the manufacturer from a certain level and whether it is suitable for mutual cooperation.

2) In order to better guarantee the product quality of pcb board and electronic components supplied by PCBA foundry manufacturers, we must look at the well-known companies that cooperate with them in the process of selecting suitable China PCB manufacturing factory. Which ones? Know if the company you are cooperating with is a well-known medium and large-scale enterprise, or whether it provides a comprehensive supporting solution for PCB Assembly for well-known brand companies; or analyze the electronic equipment business field of its production and processing. There is no current hot business area, so you can indirectly understand its production and processing capabilities. In addition, it is necessary to visit and inspect whether the manufacturer has established good quality management and comprehensive procurement strength advantages in electronic component matching, and whether the long-term and stable cooperative relationship between the manufacturer and the agent has a good delivery time and supply cost. Advantages and so on.

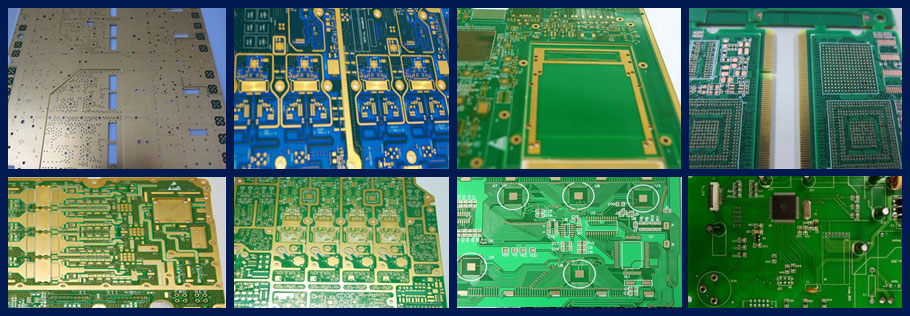

PCBA foundry material

2. What are the risks of the OEM model?

1) It is difficult to confirm the authenticity of materials

Since PCBA foundry manufacturers are responsible for the overall production of electronic components and PCBs, some electronics manufacturing factories that pursue profit may purchase some counterfeit and shoddy materials in order to reduce production costs. In this case, the quality of the materials can be ensured by appointing the material supplier and providing the original certificate of the material.

2) The procurement cycle is unstable

In the entire production cycle of PCB Assembly processing, material procurement is the most unstable, especially when the components used by the customer are scarce, not common supplies, or the demand for components is large, and the foundry has no inventory and needs to take the way of ordering At this time, uncontrollable factors will occur.

3) Difficulty in maintenance

If the PCBA foundry manufacturer does not have strong repair capabilities, it will cause difficulties in product repair and prolong the repair cycle, which will eventually affect the delivery time of the product and cause relatively large losses to customers.

4) Capital risk

The PCBA foundry production model requires China PCB manufacturer to help customers purchase all materials. Customers need to pay an advance payment, usually 70% of the total payment, then the manufacturer starts to purchase materials and conduct the PCB Assembly processing production process. Finally, when the product is shipped The customer pays the remaining 30%. As we all know, the value of PCB Assembly OEM services is generally relatively high, and the transaction amount is relatively large. In the process of cooperation between the two parties, defaulting on the accounts will easily lead to the break of the company’s funds, thus increasing many uncontrollable risks.

The above is the detailed introduction of the editor on "What should manufacturers pay attention to when using PCBA foundry materials, and what risks does it have?". If you have other questions, please continue to pay attention to us.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider