Now electronic processing industry has a one-stop processing service gradually popular, that is, PCB assembly substitute for materials mode. Today, the small edition will talk about "what should be paid attention to by the manufacturers of replacing materials by using PCBA as a substitute, and what risks does it have?"

1、 What should be paid attention to by the manufacturers of replacing materials by using PCBA?

1. During the process of selecting PCB assembly substitute manufacturer, the customer should conduct a real visit and investigation on its basic situation, especially to confirm the formal and professional ability of the manufacturer. In view of its formality, we can understand from its corresponding qualification certificate, such as whether to carry out ISO9001 quality management system certification, etc; To understand the professional ability of electronic products processing, we should be more careful. For example, go to the China PCB manufacturer to visit the site personally. The main contents of the visit include SMT patch processing and production workshop, dip production workshop, office environment, spirit of enterprise employees, etc., for example, to see if their machine and equipment are advanced, whether the PCBA production process meets the requirements and whether the working environment of the production workshop is clean and tidy, Whether the materials are placed in order, etc. Customers can also fully consider the development track of the manufacturer in recent years. If the development is better and better, then it can also judge the overall strength of the manufacturer from a certain level, whether it is suitable for mutual cooperation.

2. In order to better guarantee the product quality of China PCB board and electronic components supplied by PCB assembly OEM manufacturing, we should look at the well-known enterprises that cooperate with each other in the process of selecting suitable processing manufacturers, and understand whether the companies with which they cooperate are medium and large enterprises with high reputation, Is it a complete solution for well-known brand companies to supply PCBA; Or to analyze whether the electronic equipment business field of its production and processing has the current hot business field, so it can also indirectly understand its production and processing strength. In addition, we should visit and investigate whether the manufacturer has established good quality management and comprehensive purchasing strength advantages in electronic component matching, long-term and stable cooperation relationship between manufacturers and agents, whether it has good delivery time and supply cost advantages.

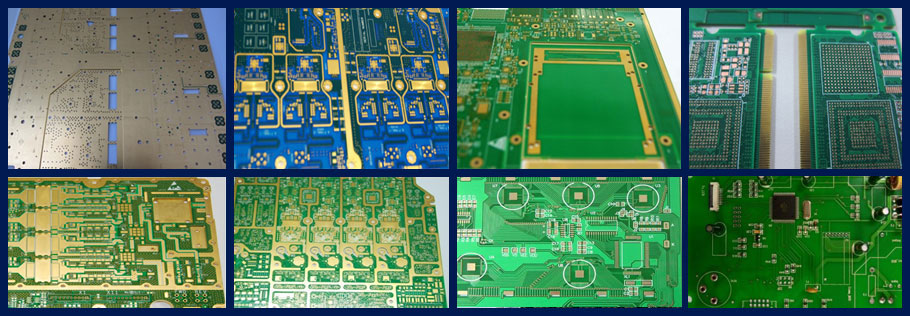

PCB assembly substitute

2、 What are the risks of the mode of substitute?

1. It is difficult to confirm the authenticity of materials

As PCBA OEM manufacturing is responsible for the overall production of electronic components and PCB, some electronic processing plants seeking benefits may purchase some fake and inferior materials in order to reduce the production cost. This can ensure the quality of the material by specifying the material supplier and providing the original origin certificate of the material.

2. Unstable procurement cycle

In the whole production cycle of PCB assembly processing, the most unstable material procurement is made, especially when the components used by customers are scarce, the demand for non regular products or components is large, and the OEM does not have inventory and needs to take the order mode, so the uncontrollable factors will occur.

3. Difficult to maintain

If China PCB factory does not have strong maintenance capability, which leads to the difficulty of product maintenance and the extension of maintenance cycle, it will eventually affect the delivery time of the product and cause a relatively large loss to customers.

4. Capital risk

The PCBA mode requires that the processing manufacturer help customers purchase all materials. The customer needs to pay the advance payment in advance, generally 70% of the total payment. Then the manufacturer starts to purchase the materials and processes the PCB assembly processing and electronics manufacturing process. Finally, the customer pays 30% of the remaining amount when the products are shipped. As we all know, the value of China PCB service is generally high, and the transaction amount is relatively large. In the process of cooperation between the two parties, the delay of the debts by one party will easily lead to the company's fund breakage, so many uncontrollable risks will be increased.

The above is a small compilation of "what should be paid attention to by the manufacturer of substituting materials by PCBA, and what risks does it have?" If you have other problems, please keep an eye on us!

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider