The biggest problem circuit designers face these days is not knowing when to opt for a Flexible PCB and when to go for its Rigid counterpart. while the issue is relatively straightforward, there's a lot of misinformation masquerading as fact on the internet which can cause you to Circuit AN ILL-Suited is the Choose Board Design for your!

the to Ensure® the happens to Never The Same Our Readers, WE've Compiled AN informative Guide Details All that you need to know About the PCB Selection.

Applications of Flexible Printed Circuit Boards:

With an ever-increasing demand of making electronic devices smaller and smaller, Flexible PCBs offer quick relief for circuit designers struggling to fit connections in limited space. Here are a few applications where you should always opt for Flexible PCBs.

1. Medical Devices:

Medical implants like artificial pacemakers are electronic devices that have intricate and complex connections. further, sticking to the example of pacemakers, they may also sustain the contractions of the heart (when the heart beats).

In this scenario, the use of a rigid PCB Would make no sense as it would not be able to sustain the constant contraction and expansion of the heart.

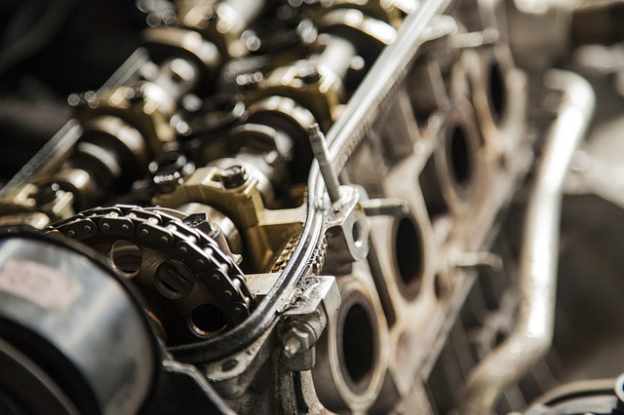

2. Automotive Applications:

Flexible PCBs are more shock and vibration resistant than their rigid counterparts. This makes them perfect for automotive applications particular in the domain inner-engine calibration and sensing.

3. Small Electronics:

Apart from its medical and automotive applications, Flexible PCBs are also great at powering miniature electronic devices. This is due to the fact that they're thinner, more lightweight, and require a lower number of interconnections to function.

Application of Rigid Printed Circuit Boards:

While flexible printed circuit boards definitely have more applications than their rigid counterparts, there are some devices that simply cannot be powered by Flexible PCBs.

4. Aerospace Engineering:

Elevated temperatures and high pressure differentials are extremely common in the domain of aerospace engineering, and this is where Rigid PCBs shine the brightest. For example, they're commonly found in Auxiliary Power Units (APUs), cockpit gauges and instrumentation, and temperature sensing Equipment, etc.

5. Automation:

Simply put, the automation industry cannot function with Rigid Printed Circuit Boards. In particular, multi-layered PCBs are used in applications that have high voltage and frequency demands such as surge suppression systems, pressure controllers, and even robotics!

6. Other Applications:

Apart from aerospace engineering and automation, Rigid PCBs are also used in all applications that have budget constraints. When a PCB manufacturer simply cannot afford to put in a flexible PCB, they rely on its rigid counterpart to do the same job.

We hope this clears May you have have the any Confusion up HAD the About the Rigid PCBs and that you now know Which of the type of PCB to use for your Circuits. HOWEVER, IF you do not want to Design your own PCBs, at The Topscom Team Would Love to Help!

We have have years Of experience under our belt and have perfected the process of creating robust and reliable SMT PCBs. So, if you want to use premium quality PCBs in your circuits, contact us today !