How to Select China Contract Manufacturing and China electronic assembly services?

Last week I gave an introduction of the electronic manufacturing services industry in China (EMS). In this post, I want to give a few hints on where electronic contract manufacturing China service are competitive and some tips on how to select them depending on your specific situation.

How to distinguish China contract manufacturing Services?

There is a wide range of EMS companies, of all sizes and with very scope of activities. Last week, I already listed different type of EMS by their size:

Top Tier manufacturers

Mid Tier manufacturers

Bottom Tier local manufacturers

There are several other aspects to consider when selecting an contract manufacturing Services, including:

The scope of activities offered by the contract manufacturing China services company;

The range of certifications they secured;

The areas where they are able to provide competitive costs;

The technical capabilities they have;

The strength of their production, procurement and quality assurance processes.

Scope of Activities

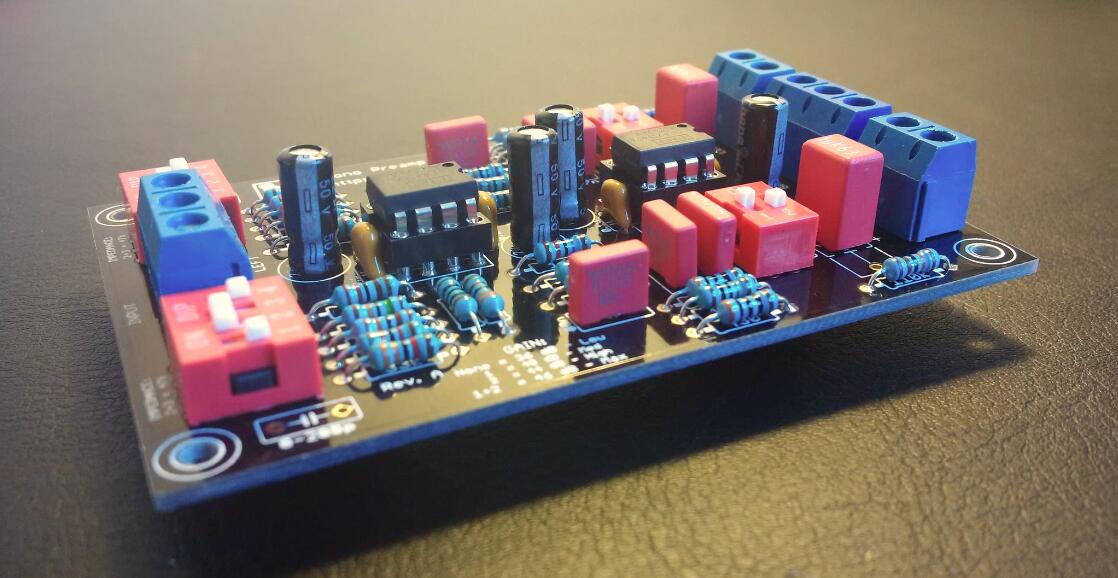

Some client will only need a PCB assembly (PCBA) to be populated with components and soldered. Others will be seeking a full turn key service from sourcing of component to final assembly and testing. It is important to evaluate the scope of activity each contract manufacturing Services can offer reliably.

All contract manufacturing services will offer some or all of the following activities:

Sourcing of components as specified by customer (electronics, enclosures, wires and harnesses);

Sourcing or fabrication of PCBs;

PCB assembly (PCBA) with PCB SMT assembly or PTH/DIP;

Testing of board (SPI, AOI, ICT, FT)

Conformance coating and other special treatment;

System assembly and testing

Technical work such as cost improvement, ODM or variant management.

Certifications

There is a wide range of standards and certification China contract manufacturing Services companies can have. The most current are:

ISO 9001,

ISO 14001

TS 16949

RoHS

Areas where China contract manufacturing Services provide competitive costs

The total cost of PCB assembly (PCBA) is mainly related to the cost of the Bill of Material (BOM). Only large China contract manufacturing Services have strong cost advantages on component because of their purchasing power. Smaller companies do not always have the best component prices.

EMS Still, contract manufacturing China Services have strong cost advantages in these areas:

DIP/PTH manual insertion

Testing of PCB assembly (PCBA) and Systems, especially when tests require many steps like for mobile phones

System assembly using PBAs and plastic or metal enclosure

Customized packing

Lower setup costs for small production batches

All these steps require skilled labor and China offers good value for buyers. It is important to understand where each supplier can bring cost advantages in the long run in order to develop a stable China PCB supplier & buyer business relationship.

Technical Capabilities

We touched upon this a little in the scope of activity. Different suppliers will have different capabilities and it is important to ensure that they really master the techniques they claim to have:

Precision of component placement on PCB;

Type of components that can be placed and soldered (PCB SMT assembly, COB, Flexible PBA . . .)

Type of test they can run: x-ray tests, fast in-circuit tests, advanced functional and environment tests …

Number of PCB laywers

Range of instruments in the China PCB factory for specific tests

Strength of production, supply chain and quality processes

Capabilities need to be evaluated like for any China PCB supplier, as we described in a previous post: What should I look for during my visit? In particular, a few areas are really important to evaluate:

Component sourcing, incoming inspection and storage

Inventory and forecast balancing: some components have long lead time and it is important to understand how much of the balancing can be done by supplier and how much must be kept in house by the buyer

QC records and analysis for each test and monitoring done.

Some China PCB manufacturer also provides advanced capabilities

Bar-code control process

Full traceability from a specific delivery to production batch and incoming goods order.

This is clearly not an exhaustive list, but considering all these items will prevent buyer from making the wrong decision when selecting a China contract manufacturing Services company.