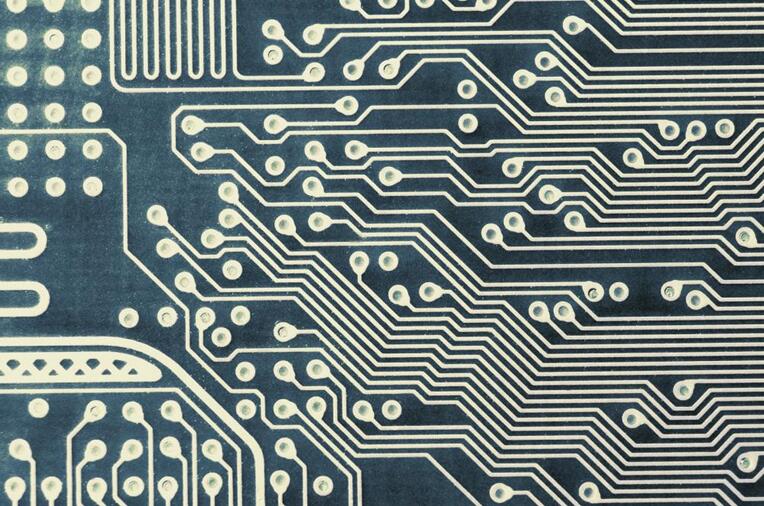

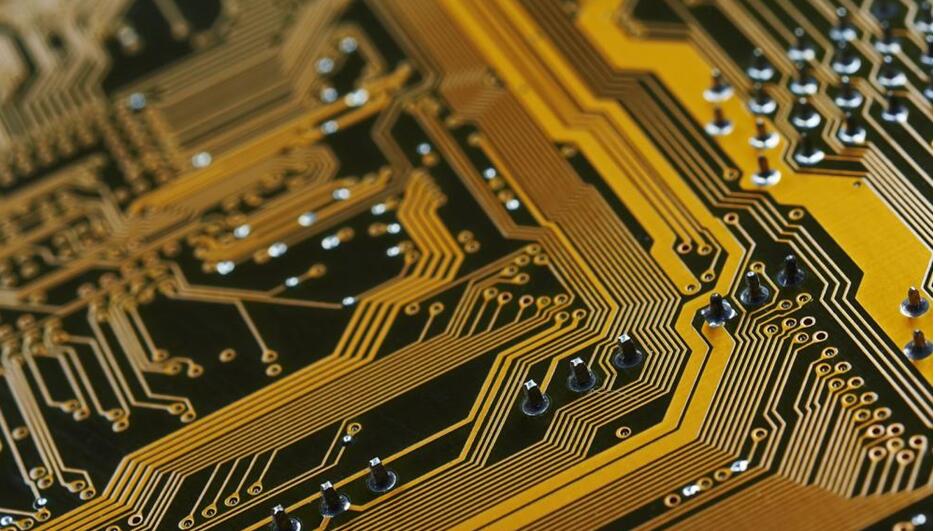

The Advantages of Using Printed Circuit Boards

Point to point wiring and soldering may have been the only option to make electrical connections in the past but Printed Circuit Boards have made the practice entirely archaic. In fact, most modern PCBs are so efficient at their job that devices with manual wiring are rarely found.

Don’t believe us? Here are just a few of the manyadvantages of PCBs that will change your mind!

1. Small Size:

It’s no secret that the size of our electronic devices has been consistently decreasing year after year. Our cell phones are now more powerful and sophisticated than ever before yet they’re getting slimmer and slimmer.

While that may sound like witchcraft at first, the answer is unbelievably straightforward; printed circuit boards. Believe it or not, PCBs are the reason why our devices have significantly decreased in size over the years.

This is because the interconnections on a PCB are much more intricate. This is done via thin current conducting wires (copper) which leads to less bulky builds and sleeker designs.

2. Cost Savings:

As discussed above, PCBs have thin copper tracks (or wires) on them. As these tracks are much slimmer than the wires used in point to point wiring, it should come as a surprise to no one that these devices come with unmatched cost-savings.

Furthermore, as the entire design is much more compact and sleek, manufacturers end up spending only a fraction of the sum they would’ve spent had they opted for point to point wiring and soldering.

3. Easy to Repair:

PCBs have also surged in popularity because it’s very easy to diagnose any problems with the design. Granted it’s much easier to do so in devices that have color-coded point to point wiring but since the practice has almost completely gone out of style, PCBs are our best bet of simplifying repairs.

4. Time Savings:

As it’s very easy to run diagnostics and fix them, it’s only natural that prolonged use of PCBs can save your organization both time and money. Where your design and diagnostics team would have to dismantle the entire board and start from scratch, PCBs allow you to save a significant amount of time by easily replacing the faulty copper wire on the board.

5. Freedom to Move:

No matter how well you solder the wires, these connections will be disturbed if your electrical network is moved suddenly. On the other hand, PCBs are one robust unit and are completely immune to movement. In other words, you can use PCBs in moving applications which simply wouldn’t have been possible with point to point wiring.

It’s because of these reasons (and countless others) that we’re such strong advocates of printed circuit boards. If you’re ever in the market for high-quality SMT PCBs, the Topscom PCB Assembly team would love to help! We’re one of the top electronic assembly companies in the world and can provide you with the robust and reliable solutions to fit your design needs!

Pick up the phone and get in touch with us for top-notch electrical and electronic solutions.