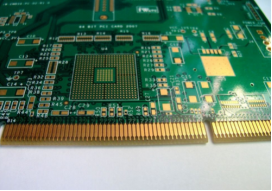

Majority of the electronics today have a printed circuit board, PCB for short, at their core. The quality and design of the PCB determines how well the components and the wiring mechanisms function. PCBs in the past were quite simple and limited in design, but today’s PCBs are quite complex. From odd-shaped varieties to flexible options, PCBs are quite varied today. However, one particular type of PCBs are making a lot of waves in the industry, i.e. multi-layered PCBs.

As the name suggests, multi-layered PCB are made with three or more conductive copper foils layers. Because of their unique design, they offer a number of advantages to electronic manufacturers:

Small Size

The most important and lauded advantage of multi-layered PCBs is mainly their small size. Because they have a layered design, multi-layered PCBs can be inherently smaller than other PCBs that provide the same functionality.This is particularly important for today’s electronics that are constantly shrinking in size. This is why we see laptops, smartphones and tablets becoming smaller but becoming more and more powerful.

Lightweight

Smaller size also means lighter weight. What’s more, the multiple connectors that are used in other PCBs to interlink the different layers are eliminated, which makes the multi-layered PCBs lighter in weight.This is again important for devices that must be light weight for more mobility.

Increased Durability

By nature, multi-layered PCBs are quite durable as compared to other types of PCBs. They can not only lift their own weight, they can also handle the pressure and heat that is used to bind them.Multi-layered PCBs also use multiple layers of insulation between different circuit layers, which is bonded with protective materials and bonding agents.

Flexibility

This may not apply to all multi-layered PCBs, but there are certain designs that do use flexible construction methods. This is a highly desirable trait for applications that go through occasional flexing and bending.The more layers a multi-layered PCB has, the more rigid its design will be.

Single Connection

Multi-layered PCBs are designed to function as single units, and not in tandem with other PCB components. This is because they have single connection point, which is essential in small gadgets that are designed for minimal weight and size.Reliable

Since making multi-layered PCBs requires a lot of work and planning, they tend to be quite high in quality as compared to double and single layer PCBs. As a result, multi-layered PCBs are quite reliable and are not known to fail.We at Topscom PCB Assembly take great pride in our ability to provide multi-layered PCBs to our clients. Our team of design engineers leverages its years of experience in the industry to create robust and reliable SMT PCBs that are built to stand the test of time!

So, if you want to use premium quality PCBs in your circuits, contact us today!