Research on the Procurement Management of Raw Materials in Electronics Manufacturing Industry.

[abstract] the industry characteristics of electronics manufacturing industry determine that raw material procurement is not only a very important part of its supply chain, but also a potential part of its cost management. This paper analyzes the importance of raw material purchasing management in electronic manufacturing industry, expounds the basic contents of raw material purchasing in modern electronic manufacturing industry, and discusses the cost control and raw material inventory control in purchasing management.

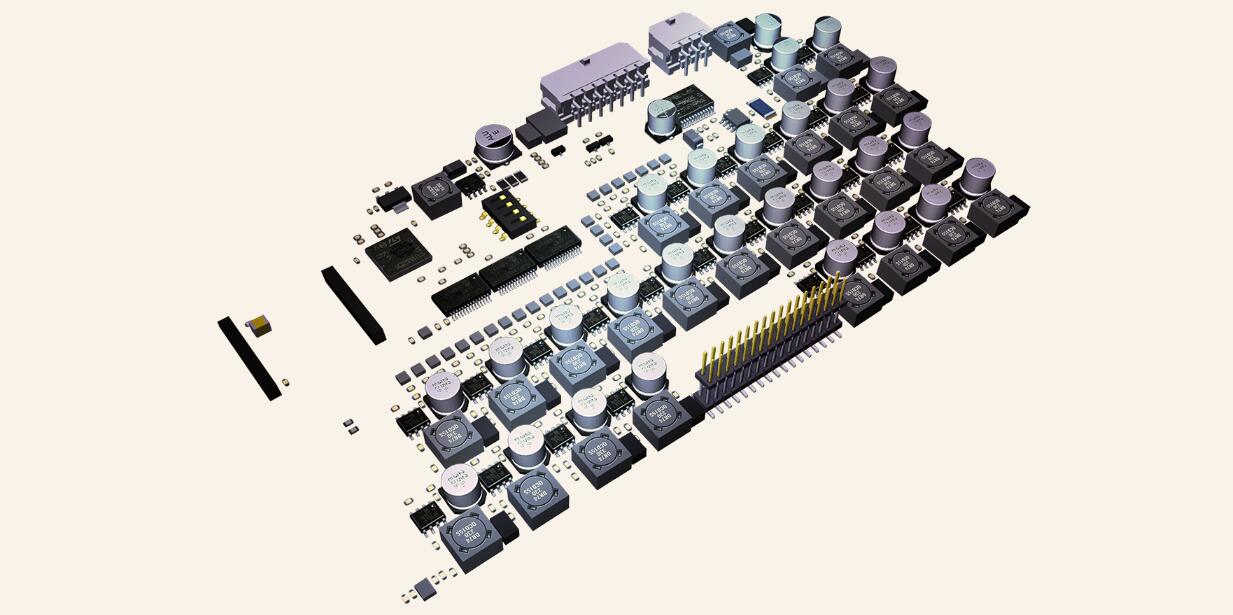

[keywords] Electronics manufacturing, raw materials, purchasing management, pcb boads assembly, pcb boad, pcb assembly, pcba

1 the importance of purchasing management of raw materials.

The procurement of raw materials in electronic manufacturing industry refers to the process that enterprises purchase raw materials, components, spare parts or related services from the outside world in order to maintain normal production, operation and services. The success and failure of countless enterprises are closely related to their supply chain strategy, specifically raw material procurement management strategy. Raw material purchasing plays a very important role in the operation of modern electronic manufacturing industry.

First of all, the procurement of raw materials of electronic manufacturing enterprises can meet the needs of production, processing or assembly in time, which is a necessary prerequisite for normal production activities. The quality and performance of raw materials and parts directly affect the quality and performance of finished products; the price and delivery time of raw materials and parts directly affect the cost and delivery time of finished products.

In the 21st century, the focus of competition in the electronic manufacturing industry has focused on agility, that is, the ability of enterprises to respond to market demand as quickly as possible. Secondly, raw material procurement is an important link for electricity manufacturing enterprises to reduce costs and improve economic benefits. the article is posted by Ms zhuang xuexian,director of Topscom Procurement department,china Topscom provide high difficulty density & printed circuit boards PCB design & layout, mass manufacturing & fabrication,pcba boards assembly, turnkey full systems integration electronic contract manufacturing services.

2 the content of raw material purchasing management in modern electronic manufacturing industry.

The purchasing management of raw materials in modern electronic manufacturing industry mainly includes the following aspects:

2.1Using MPR tools to achieve JIT procurement.

MRP is the abbreviation of Material Reuquirement Plan, that is, material requirements planning. According to the basic idea of MRP, electronic manufacturing enterprises have formed a complete method system from selling products to purchasing raw materials, from the processing of self-made parts to the supply of outsourced parts, and to produce (JIT) on time on demand.

2.2 ABC classified management of purchased materials.

For any given group class, a few items in the group category will account for most of the total value. This theory is applied to the procurement of electronic manufacturing industry, which is the ABC classification.

Category A materials are relatively few materials whose total value accounts for 70% / 80% of the final product material value. Usually 15% to 20% of the total number of materials;

Category B materials are materials whose total value accounts for 15% and 20% of the final product material value. Usually 30% to 40% of the total number of materials;

Category C materials are materials whose total value accounts for 5% and 10% of the material value of the final product. The quantity of this material is the largest, usually 60% to 70% of the total number of materials.

Class A materials should be controlled as much as possible. Including the most complete and accurate records, the most high-level supervision of the regular review, from the supplier according to the total order of frequent delivery, to closely track the production line compression lead time, and so on. Give category A materials the highest priority in all activities to reduce their lead time and inventory. For category B materials, normal control, including good records and routine attention. When dealing with B materials, only normal handling is required, and high priority is given only when it is critical. For class C materials, use the easiest control possible. Give category C materials the lowest priority when handling.

2.3Informatization management of procurement-ERP and e-commerce.

Efficient procurement management is inseparable from the reliable support provided by the information technology system. The realization of informationization is another focus of modern electronic manufacturing enterprises in the management of procurement. The information management of procurement in leading electronic manufacturing enterprises is mainly reflected in two aspects: ERP and e-commerce.

E-commerce (Electronic Commerce,EC) refers to the process in which two or more parties conduct business activities through computers and some form of computer network. There are a lot of business data to be transmitted between manufacturers, material suppliers and logistics suppliers in the electronic manufacturing industry, and the information and systems they use may not be the same. This requires an accurate and fast information transmission tool to help carry out information transmission. EDI technology is used to deal with the transmission and exchange of business data between various business partner enterprises, so it is a necessary tool for raw material management in electronic manufacturing industry.

(3) Control of purchasing cost of raw materials.

The procurement process of raw materials is divided into: preparing the purchase plan of raw materials, determining the purchase demand, selecting the supplier, determining the supply channel, setting the purchase price, implementing the best purchase, and obtaining the lowest purchase cost. How to effectively control the procurement cost must solve at least the following two problems.

3.1 identify procurement channels and reduce intermediate circulation links.

Implement the supplier evaluation system before procurement, determine the procurement channels, and reduce the intermediate flow links. Supplier evaluation is the preparatory stage for the implementation of procurement cost control. Enterprises should extensively collect market information and grasp the changes of major material information. In addition to the procurement of raw materials with special requirements, more than two supply orders should be selected for the procurement of major raw materials. Compare from the quality, price, reputation and other aspects, and examine their qualifications, and finally determine the optimal supply channels, reduce circulation links, reduce procurement costs.

3.2 controlling quality and reducing Purchasing loss cost.

Product quality is the life of the enterprise, the quality is directly related to the market share of the enterprise, and the quality of raw materials is an important factor that determines the product quality of the enterprise, so the procurement of raw materials should first ensure good quality. In general, the quality is good, the price is low, the quality is poor, the price is low, how to achieve high quality and low price, only to compare the goods and establish the procurement cost optimization model: for the main raw materials that directly affect the product quality, carry out quality inspection and verification, strictly control the quality, establish a quality and cost tracking system for the main materials, timely adjust the supplier, and seek the optimal procurement cost on the basis of comparing quality and price. For the materials with large daily consumption and little impact on product cost, they focus on the comparison of their prices and purchase at low prices.

4 control of raw material inventory.

The control of raw material inventory is closely related to material procurement. As a dynamic variable that must be timely adjusted in the production and operation of enterprises, it is affected by many factors. The value of stock materials will increase or decrease with the rise and fall of market prices. Predicting price trends, mastering the law of price changes, and timely adjusting inventory can obviously obtain benefits beyond the benefits of production and processing. However, in order to ensure the normal progress of production, it is necessary to ensure a minimum inventory when the price is expected to fall; when it is predicted that the price will rise, there will also be a maximum inventory, and it should be considered that it is subject to the size of inventory capacity, the limitation of the amount of capital adjustment, the comparison of the rate of price increase with the interest rate of capital, and whether the price will fall before it is put into production and consumed.

4.1 Raw material inventory control and financial expenses.

The financial expenses of an enterprise are the interest paid by the enterprise for the use of funds. The cost of raw material inventory consists of interest, storage fee, storage fee and storage loss of the occupied funds. In the enterprise, because the warehouse administrator and the warehouse are relatively stable, the cost is fixed, and the financial cost increases with the increase of the amount of inventory materials, that is, the inventory cost is composed of fixed cost and variable cost. In order to reduce this cost, we must start with variable cost. In terms of cost control, the lower the inventory, the better. However, the inventory of raw materials must ensure the normal operation of production. the article is posted by Ms zhuang xuexian,director of Topscom Procurement department,china Topscom provide high difficulty density & printed circuit boards PCB design & layout, mass manufacturing & fabrication,pcba boards assembly,turnkey full systems integration electronic contract manufacturing services.

4.2 ensure minimum inventory of raw materials.

The minimum inventory of raw materials is to ensure that when enterprises find that raw materials are tight, there is enough inventory to ensure production, so that production will not be affected by untimely procurement. However, in order to consider the impact of transportation accidents, the safety factor must be set and adjusted in time in the raw material procurement management system. If the purchase time is less than one working day, zero inventory control can be adopted. this kind of materials are generally long-term products, and there are more suppliers in the region, which can be notified and delivered at any time. If the consumption of a certain raw material is less than a certain value, it is enough to purchase in bulk, but when the purchase time is long, and the total batch price difference is not enough to pay the travel and salary expenses of the purchasing personnel, the fixed value is not less than the minimum purchasing quantity. Can take the contract agreement, regular delivery, is also a kind of zero inventory management. When the consumption is too small to obtain the wholesale price of manufacturers and wholesalers, it can only allow the logistics center of the local city to reserve and operate, or because the reserve is small and the level of professional reserve is not high, so that the reserve expense rate is greater than the working capital loan interest rate, it is also necessary to allow the local logistics center to reserve and operate.

4.3 due to the supplier's sales strategy.

The purchase of raw materials should be made according to the length, width and marketing strategy of the supplier's sales channel, because the length, width and width of the sales channel directly affect the purchase time, and some reflect time is short, transportation time is long, some reaction time is long, transportation time is short, or both are long or short. The credibility of the supplier, whether it can abide by the contract and the willingness to bear the liability for breach of contract are all very important. Therefore, an appropriate inventory mode must be established according to the characteristics of the enterprise, which are as follows: actual inventory = stable monthly supply + unstable monthly supply-monthly consumption minimum inventory; due to the fluctuation of unstable monthly supply, the actual inventory must be greater than or equal to the minimum inventory, so there must be: monthly consumption ≤ stable monthly supply + unstable monthly supply; It can be seen that the actual inventory is affected by unstable monthly supply and must be greater than the minimum inventory.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider