The latest technology of SMT surface mount, looking at the development trend and prospect of the SMT placement machine for Pcb Assembly .

Topscom Group SMT Workshop Lab Dr.Wang jinting. Issured On March,10, 2020.

What is the Introduction of the latest smt surface mount technology ?

Abstract: this paper expounds the development course and technical characteristics of the third generation placement machine, puts forward the requirements of "seven smt indicators" (high performance, high efficiency, high integration, flexibility, intelligence, green, diversification) in the future development stage, introduces the systematic process advanced assembly process control APC, and predicts and evaluates the development prospect of the placement machine, which can be used as a reference for colleagues engaged in the research and development of the placement machine.

Keywords: electronic manufacturing, electronic pcb assembly, pcb smt assembly, SMT placement machine Pcb Board

1 introduction.

Electronic manufacturing industry is a strategic, basic and leading pillar industry of the national economy, which is very important for stimulating economic growth, strengthening national comprehensive strength, accelerating modernization and maintaining national security. After years of sustained and rapid development, China's electronic manufacturing industry has become the largest manufacturing base of electronic information products in the world. At present, it is in a critical period of transformation and upgrading of industrial structure and development mode, and from a big electronic manufacturing country to a powerful country.

Placement machine is a typical high-speed, high-precision, high-efficiency key special electronic equipment in the electronic manufacturing production line, which usually accounts for more than 60% of the investment of the whole SMT production line, and is the bottleneck of the efficiency of the production line. It is also the most challenging modern manufacturing equipment technology that embodies "modern, white-moving, intelligent" production.

Placement machine is the basic equipment of electronic manufacturing, and the importance of equipment to the manufacturing industry is obvious. As the ancients said, "if you want to do good work, you must first sharpen its tools." although electronic manufacturing is an advanced manufacturing technology developed in modern times, things are roughly the same. However, the ancient "tools" are only simple machinery and manual tools, lack of sharp tools, and may only involve efficiency and quality, while modern electronic manufacturing is completely different without corresponding modern semiconductor manufacturing equipment. it is impossible to produce the chips needed for all kinds of terminal electronic information products that are changing with each passing day. Without efficient advanced electronic assembly equipment, circuit boards that are getting smaller and closer can not be assembled, and your products will not be able to compete in the international market at all.

2 the development of placement machine.

2.1 the first generation placement machine.

In the 1970s, with the performance advantages of surface mount chips and chip components, surface mount technology was mainly used in military, aviation, aerospace and other cutting-edge products and investment products, and gradually widely used in computer, communications, industrial control and other industries, and extended to consumer electronic products. SMT has increasingly become the mainstream technology of electronic assembly and manufacturing. Driven by the strong market demand, the first generation placement machine came into being. Although the mechanical alignment method adopted by the placement machine at that time determined that the placement speed was low (about 1000 ^-2000 pieces / h), placement accuracy was not high, CX-Y positioning accuracy was 0.1mm), and the function was simple, it already had all the elements of modern placement machine, compared with manual placement and simple manual placement machine. This speed and precision is undoubtedly the new beginning of the revolution of electronic assembly technology.

The first generation placement machine has created a new era of large-scale all-white movement, high efficiency and high quality production of electronic products. For the relatively large chip components in the initial stage of the development of SMT (Chip component type is 1608, IC pitch is 1.27 ^ 0.8 mm), it can already meet the demand of mass production. With the continuous development of SMT and the miniaturization of components, due to the poor positioning accuracy of pure mechanical mechanism, the risk of damage to fine chip components by mechanical grabbing, and the excessive impact of Z-axis drive on SMD and PCB, this generation of placement machine has long been out of the market and can only be seen in a few small enterprises.

2.2 second generation placement machine.

From the mid-1980s to the middle and late 1990s, the SMT industry matured and developed rapidly. driven by it, the second-generation placement machine adopted optical system on the basis of the first generation placement machine, and the development of numerical control and precision motion control technology became more and more mature, which greatly improved the speed and accuracy of the placement machine and met the needs of the rapid popularization and rapid development of electronic products.

In the process of development, it has gradually formed a high-speed machine (also known as Chip component mounting machine or shooting machine), which is mainly for mounting Chip components and emphasizing mounting speed, and multi-functional machines (also known as universal machine or IC mounting machine) for mounting all kinds of IC and special-shaped components, which are obviously different in function and use. in the process of development, it has gradually formed a high-speed machine (also known as Chip component mounting machine or shooting machine) with different functions and uses.

(1) High speed machine.

The high-speed machine mainly adopts rotary multi-head and multi-suction nozzle sticker head structure, which can be divided into turret type (rotation direction is parallel to PCB plane) and wheel type (rotation direction is perpendicular to PCB plane or 45 degrees) according to the rotation direction and PCB plane angle, so that the mounting efficiency and speed can be doubled.

Due to the use of optical positioning and alignment technology, precision mechanical systems (ball screw, linear guideway, linear motor and harmonic driver, etc.), precision vacuum system, various sensors and computer control technology, the mounting speed of the high-speed machine has reached the order of magnitude of 0.06 s / piece, which is close to the limit of the electromechanical motion control system.

(2) Multi-function machine.

Multi-functional placement machine, also known as universal machine, can mount various sizes of packaged chips and a variety of special-shaped components, as well as small chip components, which can cover a variety of components of different sizes and shapes, so it is called multi-function placement machine. The structure of the multi-function placement machine mostly adopts the arch structure and the translational multi-suction nozzle sticker head, which has the characteristics of high precision and good flexibility. The multi-function machine emphasizes function and precision, and the mounting speed is not as fast as that of the high-speed placement machine. it is mainly used for mounting all kinds of packaging IC and large and special-shaped components, and it is also used for the placement of small chip components in small and medium-sized production and trial production.

With the rapid development of SMT and the further miniaturization of components, the emergence of more fine SMD packaging forms such as SOP, SOJ,PLCC, QFP, BGA, especially in the face of the demand of multi-variety and small batch flexible production mode, this generation of placement machine is also gradually unable to achieve, and has gradually withdrawn from the field of vision of the mainstream placement machine manufacturers.

2.3 third generation placement machine.

From the end of 1990s to the beginning of the 21st century, driven by the rapid development of SMT industry and the diversification of demand and variety of electronic products, the third generation placement machine has been developed. On the one hand, all kinds of IC new microminiaturized packaging and metric 0402 chip components put forward higher requirements for chip mounting technology; on the other hand, the complexity and installation density of electronic products are further improved, especially the trend of multi-variety and small batch, which promotes the mounting equipment to meet the needs of assembly technology packaging.

The main features of the third generation placement machine-high performance and flexibility.

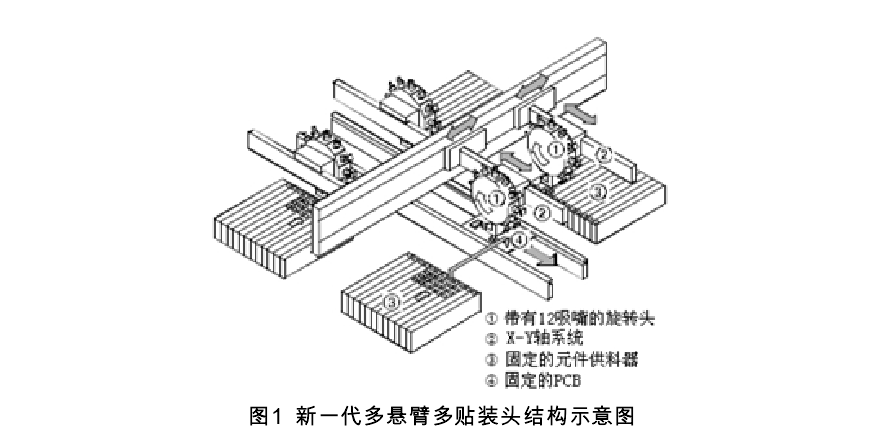

Combine high-speed machine and multi-function machine into one: through the flexible structure of modular / modular / cell machine, the functions of high-speed machine and general-purpose machine can be realized on one machine by selecting different structural units. For example, the placement range of white 0402 elements to 50 mmX 50 mm, 0.5 mm pitch integrated circuits and 150000 cph placement speed are realized.

Strike a balance between speed and accuracy: the new generation of placement machines uses high-performance placement heads, precision visual alignment, high-performance computer software and hardware systems, such as 45,000 cph on one machine and 50 u m or higher placement accuracy at 4 Sigma.

High-efficiency placement: the actual mounting efficiency of the placement machine can reach more than 80% of the ideal value through technologies such as high-performance chip head and intelligent feeder.

High quality placement: for example, accurate measurement and control of the mounting force in the Z direction to make the components in good contact with the paste, or the application of APC to control the placement position to ensure the best welding effect.

The production capacity per unit site area is 1 ^-2 times higher than that of the second generation machine.

Stacked (PoP) assembly can be realized.

Intelligent software systems, such as efficient programming and traceability systems.

Topscom Group SMT Workshop Lab Dr.Wang jinting. Issured On March,10, 2020.

3 development trend of placement machine.

The development trend of the future placement machine can be summarized by "seven smt indicators", that is, high performance, high efficiency, high integration, flexibility, intelligence, green and diversification.

3. 1 High performance.

In the development of placement machine, speed, accuracy and placement function have been in a contradictory state, forcing people to make a compromise between speed and precision, so high-speed machine and multi-function machine are still in operation so far. However, in the fierce competition that the update speed of electronic products is getting faster and faster in the future, and the trend of multi-variety and small batch manufacturing is becoming more and more mainstream, the new packaging, such as BGA, FC,CSP,PoP, has higher and higher requirements for the placement machine, and the placement machine mode must keep pace with the times. With the development of modularization, modularization, two-way transmission, multi-cantilever, multi-mount head structure, as well as food and travel alignment, lightning mounting and other placement technology, in a placement machine, taking into account speed, precision and placement function has become a new direction. A new type of high-performance placement machine with high speed, high precision, multi-function and intelligence will become the mainstream.

Figure 1 is a schematic diagram of the structure of a new generation of multi-cantilever and multi-mount heads.

3. 2 High efficiency.

High efficiency means improving production efficiency, reducing the number of questions asked at work, and increasing the production capacity per unit of time. To be good, fast and save money is the eternal pursuit of the manufacturing industry, especially in today's increasingly fierce competition. The main way to improve efficiency is to become white and intelligent, that is, to reduce human labor, strengthen, prolong, and replace human labor-related technology or means. From white motion control, white motion regulation, white motion compensation, white motion identification, etc., to a higher level of white movement, such as white learning, white organization, white maintenance, white repair and so on. Whitening is always realized with relevant machinery or tools. Informationization, computerization and networking have not only greatly liberated people's physical labor, but also, more importantly, effectively improved the level of mental work and liberated part of people's mental work.

For the placement machine, which is a white CNC equipment, the efficiency of software programming is very important to improve the efficiency of the equipment. Develop a more powerful software function system, including various forms of PCB boards files, directly optimize the generation of patch program files, reduce the time of manual programming, develop machine fault diagnosis system and integrated management system for mass production, and realize intelligent operation.

To an important link in the development of high-efficiency placement machine.

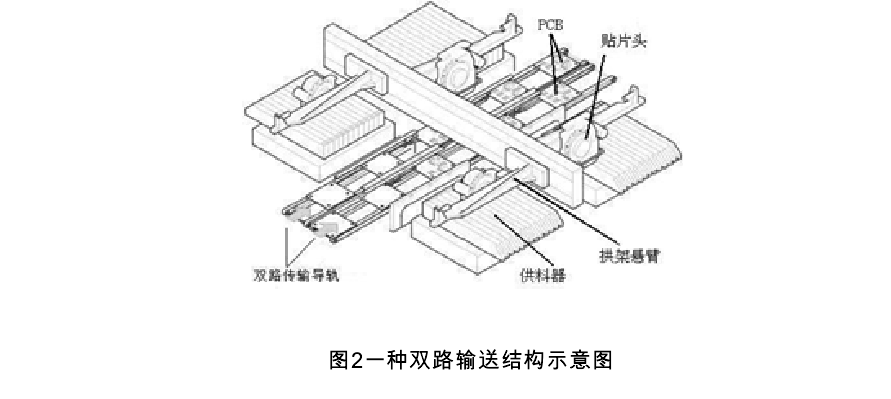

On the other hand, the improvement of equipment structure and working mode is also an important way to improve production efficiency. For example, the placement machine in the placement speed potential mining there is not much space, the structure is an effective way to improve efficiency. On the basis of retaining the performance of the traditional single-channel placement machine, the two-way placement machine designs the conveying, positioning, testing and placement of PCB board into a two-way structure. This two-way structure can work synchronously or asynchronously, which can shorten the invalid working time of the placement machine and improve the production efficiency of the machine. For example, the multi-cantilever and multi-mount head structure of the placement machine are all effective methods.

Figure 2 is a schematic diagram of a two-way conveying structure.

3.3 High integration.

High integration, one is the integration of equipment technology, the other is the integration of technology and management, and its essence is the integration of knowledge. The integration of equipment and technology requires the intersection, grafting and integration of a variety of technologies. For example, the integration of machine and optoelectronics, detection and sensing technology, information processing technology, white control technology, servo transmission technology, precision mechanical technology, overall system technology comprehensive application, software and hardware technology coordination and integration and so on. The integration of technology and management is to make full use of computer, whitening and network technology, and the organic integration of equipment application in management technology, especially the complete set of equipment that is the white production line is particularly important. For example, SMT production line equipment embedded SPC (statistical process control, statistical process control), traceability system, etc., can give full play to equipment efficiency and improve production capacity and quality.

3.4 flexibility.

The biggest challenge of electronic product manufacturing in the future is multi-variety, small batch and short cycle. The only effective way to adapt to this basic trend is the flexibility of mounting equipment.

An important mode of flexibility of the placement machine is the modularization and modularization of the equipment. Modularization is also called building block type, for example, the host of the placement machine is made into standard equipment, equipped with a unified standard base platform and a general user interface, and the various functions of the dispensing patch are made into functional module components. users can install required functional module components or replace new components on the host according to their needs to achieve the new functional requirements that users need. Modularization can be understood for the parent mode, for example, the placement machine is divided into control host and function module machine, according to the different needs of users, the flexible combination of control host and function module machine to meet the needs of users. The module machine has different functions, and according to the mounting requirements of different components, it can be mounted according to different precision and speed, in order to achieve higher use efficiency. When users have new requirements, new functional module machines can be added as needed; when orders increase, the number of module machines can be increased to increase production capacity without adding new machines.

Another mode of flexibility of the placement machine is that one machine is multi-purpose. For example, using "dispensing head" and "printing head" instead of pasting head to realize the function of dispensing machine and printing press, this performance is particularly useful for scientific research and product development institutions. Of course, this mode must take into account the compatibility of the mode and the adaptability of the interface in the mechanical structure, electrical control, computer software and hardware and other aspects of the machine design.

For a further introduction to flexibility, see the next article.

3.5 Intelligent.

The intelligence of manufacturing equipment is the most promising direction in the development of manufacturing technology. In the past 20 years, the manufacturing system is changing from energy-driven to information-driven, which requires the manufacturing system not only to be flexible, but also to show intelligence. in order to cope with the processing of a large number of complex information, rapidly changing market demand and the complex environment of fierce competition.

The foundation of intelligent placement machine is computer intelligence technology. The intelligent placement machine has the following characteristics:

Man-machine integration;

White law ability;

White organization and super flexibility;

Learning ability;

White detection and white maintenance ability.

The intelligent placement machine in the future will have a more advanced human-like thinking ability. with the help of the intelligent activities of human experts simulated by computer, it can analyze, judge, reason, conceive and make decisions on the mounting process to replace or Yanzhong part of the mental work of people in the manufacturing environment. At the same time, collect, store, process, improve, share, inherit and develop the intelligence of human experts.

The application of intelligence in mounting equipment has just begun, and the mounting function is organically integrated with the detection and analysis function to improve the level of intelligence. for example, the placement machine equipped with intelligent system can be based on the detected abnormal phenomena (faults). Analyze the root cause of the fault and correct it or give suggestions for improvement.

3.6 Greening.

Green is the inevitable trend of the development of electronic manufacturing in the future. The development of human society is bound to move towards the harmony between people and the white world, and the placement machine is no exception.

The future mounting equipment should start from the conception, in the design stage, manufacturing stage, sales stage, use and maintenance stage, until the recovery stage, remanufacturing stage, we must fully consider the impact on the environment, improve material and energy efficiency, reduce energy consumption, and maximize the benefit of user investment.

In recent years, there has been a connotation of the concept of greening and environmental protection, the so-called environmental protection is in a broad sense, not only to protect the Bai ran environment, but also to protect the social environment, production environment, but also to protect the physical and mental health of producers. Under this premise, we can produce mounting equipment with high precision, high efficiency, high quality, short supply period and good after-sales service.

3.7 diversification.

Today's world is a pluralistic and diversified world. The development of different countries and regions is not balanced, and different regions of the same country are not balanced, so there is a diversified demand for the level and grade of electronic products; at the same time, different application fields have different requirements for the application environment and reliability of electronic products, which also leads to diversified requirements for product manufacturing processes and equipment.

This diversified demand will be the intersection of diversified structure and technology for the future development of mounting equipment:

The multi-functional and flexible general placement machine suitable for a variety of products and the high-efficiency special placement machine for specific areas and products coexist at the same time.

The all-white moving, intelligent, high-precision, high-capacity high-end placement machines serving large enterprises and high-density assembly, and the middle and low end suitable for small and medium-sized enterprises and general electronic products all have their own survival and development space.

High-performance, mainstream placement machines for large-scale manufacturing in industry and small non-mainstream placement machines suitable for scientific research, teaching and laboratory are developed together.

Due to the continuous miniaturization of electronic products, 3D assembly and the application of SiP, PoP in more products, "card-level" assembly has penetrated into the field of semiconductor packaging, that is, the accuracy of the placement machine is required to meet the requirements of wafer assembly directly on PCB board. On the other hand, the object dealt with in the field of semiconductor packaging is not just wafers, passive components or other micro-components need to be embedded in some packaging modules, thus extending down to the field of assembly, the intersection and penetration of this technology, so that the boundary between semiconductor-level placement machine and card-level placement machine is blurred, the organic integration of the two new placement machine will be an important development trend.

4 brief introduction of mounting APC technology.

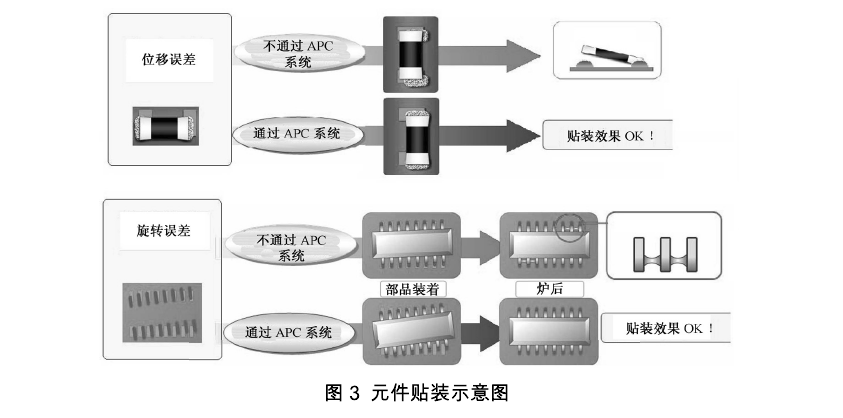

APC CAdvanced Process Control) technology is an advanced assembly process control technology, its basic idea is to consider the solder paste coating, component mounting and reflow soldering process as a whole, in order to achieve the best assembly effect.

The optimization of alignment datum in component placement is one of the application examples of APC. As shown in figure 3, the traditional component mounting center is based on the solder pad figure on the printed circuit board (strictly speaking, it is based on the circuit board design circuit diagram). Due to the inevitable manufacturing and positioning errors in circuit board manufacturing and solder paste coating, displacement errors and rotation errors will occur between the actual solder paste coating pattern and the pad pattern. Through the test, it is found that if the solder paste coating error is not considered and the pad pattern is still used as the alignment reference, the possibility of defects after reflow soldering is much greater.

With the application of APC technology, we take the actual solder paste coated pattern as the benchmark for component mounting, which can prevent defects in a certain range. There are two ways to achieve this positioning:

(1) Detection and adjustment method.

The detection of solder paste after coating and the solder paste printing machine with detection function have been applied in practice. the inspection results after printing are input to the placement machine, and the X, Y and of the mounting point are adjusted according to the offset of each printing paste. (angle) after the coordinates are mounted on it, of course, there are still a series of practical technical problems to be solved in the specific implementation.

(2) Solder paste reference method.

The basic idea of this method is to use the position of the actual solder paste coating pattern in the placement machine as the benchmark rather than the copper foil pattern on the printed board. This method requires that the solder paste pattern is applied at the position where the solder paste is applied as the reference point, and the PCB is positioned with this figure as the reference point in the placement machine. In the specific implementation, because the edge of the solder paste pattern is irregular and it is a three-dimensional figure, it is more difficult to identify the solder paste pattern than the copper foil pattern. But it is obvious that the process is simple and the speed is dominant.

5 the prospect of placement machine.

The future prospect of placement machine is closely related to electronic assembly and manufacturing technology. According to the current research and development of technology, there are the following kinds of revolutionary and subversive electronic assembly and manufacturing technologies in the future:

(1) reverse assembly technology.

In recent years, a new electronic manufacturing process called reverse assembly (also known as Occam process) has attracted much attention. Although this technology is still in the stage of laboratory research and evaluation, the innovation of process ideas and advantages over conventional processes are refreshing.

The so-called "reverse assembly process"

It is relative to the conventional process. In the conventional electronic assembly process, no matter through-hole insertion or surface mount, the printed circuit board is designed and manufactured first, and then the components are installed on the printed circuit board and connected by welding, that is, wiring first and then installing the components; the "reverse assembly process" is to place the components before wiring, which integrates PCB manufacturing and assembly manufacturing. Because the reverse assembly process does not need welding, it avoids a variety of reliability risks and uncertainties caused by lead-free, especially the advantages of green process and process simplification, which is a new process in the electronic assembly industry.

For the placement machine, the Oakham process has only changed the mounting process from the second step of the typical SMT process to the first step, and the adhesive chip components have been changed from solder paste to other adhesives. It is obvious that the Oakham process will not be the Terminator of the placement technology.

(2) full printing electronic technology.

Full-printed electronic technology, which shows infinite charm based on organic electronics and nanotechnology, is a new subversive electronic manufacturing technology. This technology makes all kinds of electronic functional materials directly realize the function of electronic equipment or system through traditional printing technology or 3D printing technology. the traditional electronic assembly processes such as component manufacturing, printed circuit board, assembly and welding circuit board are all unnecessary, and the placement machine has no opportunity to display its talents.

In recent years, with the emergence of new technologies and products on the market, such as bendable mobile phones, transparent mobile phones and televisions, large curved screen TVs, soft paper displays, translucent thin film solar cells, fully printed electronic labels, Google Glass and smartwatches, it shows that a new generation of flexible and personalized electronic era has arrived.

However, printed electronic technology does not have the high precision and high density of traditional silicon-based microelectronic manufacturing technology, and the performance of printable electronic materials is worse than that of crystal materials that traditional silicon-based microelectronics rely on. Therefore, at present, it can replace part of the traditional manufacturing technology in some fields, such as display, thin film battery, electronic label and so on. There is a lot of uncertainty that the printing electronic technology has really become the Terminator of the placement machine technology.

(3) Optics and optical path technology.

The faster the running speed of the chip of electronic products, the higher the integration, the greater the energy consumption, the body is also easy to heat, at the same time, limited by the bottleneck of nanometer size, integrated electronic devices have begun to be restricted. The subversive technology of replacing "circuit" with "optical path", "bare chip" instead of traditional "electronic chip", "optical element" replacing traditional "electronic component", and "optical circuit board" replacing traditional "circuit board", due to its huge advantages in reducing energy consumption and improving speed, has attracted continuous attention and unremitting exploration in the scientific and technological circles, and a series of encouraging progress has been made in recent years.

However, compared with the electronic technology that has been developed for many years, light technology still has a long way to go. In addition to its definite status in information transmission, in information collection and processing, especially in the implementation of information terminals, the advantages of electricity and electronic technology are almost difficult to move, and the most feasible way is "optoelectronic combination".

Therefore, the end of the optical path technology placement machine, in the foreseeable for a long time, will not appear. To say the least, even if science and technology develops to the stage of "replacing electricity with light", bare chips and optical components are still inseparable from "placement" and "connection" in order to assemble optical circuit boards, and equipment such as placement machines is still indispensable.

(4) other assembly technologies.

With the development of information technology, other revolutionary assembly technologies are also being explored, such as electric field assembly technology based on biological technology, fluid assembly technology and polyhedron devices and so on. It is difficult to predict how far these technologies will go, and it is even more difficult to predict which one will replace the popular assembly technology or complement each other in the future. But it is obvious that to explore the vast sky where a hundred flowers can blossom, industry is actually a ruthless survival of the fittest.

6 concluding remarks.

As a typical high-speed, high-precision and high-efficiency key special equipment in the electronic manufacturing production line, after decades of development, although the technology has been quite mature, the developing electronic information industry has put forward higher and higher requirements for mounting technology and equipment, such as the application of new chip packaging FC, CSP, WLP, PoP and metric 0315, 0201 chip components. It has made the precision and function requirements of the placement machine close to the field of semiconductor equipment, and the electronic manufacturing industry will have higher and higher requirements for the technical performance, flexibility, intelligence and reliability of the placement machine.

Facing the era of Internet + and big data, the manufacturing of electronic products, as the foundation of the information age, has a pillar, basic and strategic important position for the development of science and technology and the national economy. Although various future revolutionary and subversive electronic manufacturing technologies are constantly emerging, developing and exploring, the traditional silicon-based electronic manufacturing is still irreplaceable for a long time. The placement machine still has a broad development prospect.

Hello, welcome to visit our official website!

+86 13502814037 (What's up)sales@topscompcbassembly.com

Turnkey Pcba Assembly & Contract Electronic OEM Manufacturing Provider